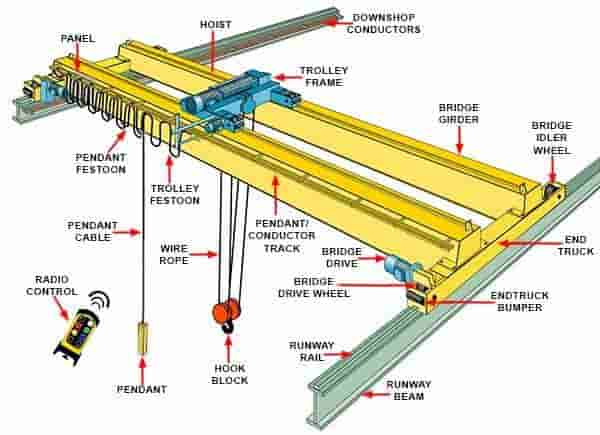

1 ton overhead crane comes in numerous types and sizes for many different purposes. It is usually configured in single girder design to handle 1 ton weight. This lightweight overhead crane is a simple lifting equipment that basically consists of one bridge girder, two end trucks, hoist, crane travelling mechanism and electrical system. We also offer tailor-made overhead cranes to suit your special lifting requirements.

Below is an overview of a price list for 1-ton bridge cranes based on different spans. Please note that these prices are for reference only and may vary due to factors such as brand, configuration, regional differences, customization needs, and market supply and demand conditions.

| Span (meters) | Price Range (RMB) |

|---|---|

| 7.5 | Approximately 5,000 – 6,000 yuan |

| 10 | Approximately 6,000 – 8,000 yuan |

| 12.5 | Approximately 8,000 – 10,000 yuan |

| 16.5 | Approximately 10,000 – 15,000 yuan |

| 20 | Approximately 15,000 – 20,000 yuan |

| 28.5 | Approximately 20,000 – 25,000 yuan (or higher, depending on specific configurations and needs) |

Explanation:

In order to obtain accurate price information, you can contact our online customer service, or tell us your needs by email, and we will provide you with the latest price as soon as possible.

Most commonly used small material handling equipment, suitable for most factories, warehouses, etc.

1 ton LD single-beam overhead crane is a lifting equipment with compact structure, easy operation and economical and practical. The crane is designed and manufactured in accordance with relevant national or industry standards, such as GB3811-2008 “Crane Design Specifications” and JBT1306-2008 “Electric Single-beam Crane”. It adopts a single-beam structure, and the main beam and the end beam are connected by high-strength bolts to form a stable lifting platform. This design not only reduces the deadweight of the crane, but also reduces the building clearance height, allowing the crane to be flexibly used in various industrial environments.

In terms of lifting mechanism, 1 ton LD single-beam overhead crane is usually used in conjunction with electric hoists in the form of CD1, MD1, etc. As a lifting mechanism, the electric hoist has the advantages of small size, light weight and easy operation. It can lift and lower heavy objects smoothly to meet the needs of various light lifting operations.

In addition, the trolley running mechanism of the crane adopts four-wheel drive, and the drive motor is a conical brake motor. This design makes the crane more stable and reliable during operation. At the same time, the crane is also equipped with a ground control button box, through which the operator can start, stop, change direction and other operations of the crane. This control method is not only simple and easy, but also improves the operating performance and operating indicators of the crane.

In terms of safety, the 1-ton LD single-beam overhead crane is equipped with a variety of safety protection devices. For example, the limit switch can prevent the crane from exceeding the working range; the brake can quickly brake the crane in an emergency to ensure the safety of personnel and goods.

Ldp Low Headroom Single Girder Overhead Crane

It is designed for low-height room, suitable for limited lifting space but high lifting height.

The 1-ton low-headroom single-beam overhead crane is a lifting equipment designed for space-constrained environments. It has a compact structure and small size, and can complete operations at a lower headroom height. It is suitable for a variety of industrial and commercial sites.

The main feature of this crane is its low design, which enables it to operate efficiently in highly restricted spaces. The frame structure composed of its main beam and end beams ensures sufficient strength and stability to withstand a rated lifting weight of 1 ton. At the same time, the trolley running mechanism and the trolley running mechanism of the crane are responsible for lateral and longitudinal movement respectively, allowing the crane to move flexibly in the working area to meet various operating needs.

In terms of lifting operations, the 1-ton low-headroom single-beam overhead crane usually uses an electric hoist as the lifting mechanism, and drives the transmission device through an electric motor to realize the lifting and lowering movement of the goods. The electric hoist has the advantages of small size, light weight, and easy operation, making the crane more efficient and stable during operation.

In addition, the crane is also equipped with a complete electrical control system and safety protection devices. The electrical control system realizes the lifting, moving, stopping and other actions of the crane through a control box or remote control, which is easy to operate and responsive. Safety protection devices include limit switches and overload protection devices, which can cut off the power supply in time when the crane exceeds the working range or is overloaded, ensuring the safety of personnel and goods.

Due to its low design and high flexibility, the 1-ton low-headroom single-beam overhead crane has been widely used in many fields. For example, on automated production lines, it can be used for material handling, parts assembly and other operations; in warehouse environments, it is often used for lifting and shifting goods to improve space utilization and work efficiency. In addition, it can also be used for maintenance and repair, construction sites, agricultural applications, and lifting operations in special environments (such as low-headroom tunnels, underground passages, etc.).

HD Electric Hoist Overhead Crane

New General-purpose crane designed with europe standards, modular design, maintenance-free.

HD electric hoist overhead crane is a lifting equipment that combines efficiency, flexibility and safety, designed to meet the diverse needs of modern industrial environments. Its core feature is the use of European electric wire rope hoists as lifting mechanisms. This design not only ensures the smoothness and precision of lifting operations, but also gives the crane excellent durability and reliability.

European electric wire rope hoists are famous for their exquisite craftsmanship and advanced technology. Through the modular design concept, the entire hoist structure is compact, easy to install and maintain. Modular design means that each component can be quickly disassembled and replaced, greatly reducing maintenance costs and time, and also facilitating equipment upgrades and modifications to adapt to possible future changes in operating requirements.

In addition, the maintenance-free nature of the hoist is another highlight. The use of high-quality materials and advanced lubrication technology ensures that the hoist can still maintain excellent performance under long-term, high-load operations, reducing the need for regular maintenance, and saving users valuable time and resources.

HD electric hoist overhead crane combines these advantages, not only can efficiently complete the lifting, handling and stacking tasks of various goods, but also because of its flexible operation and strong carrying capacity, it has become an ideal choice for a variety of industrial sites such as warehouses, workshops, logistics centers, etc. Whether it is heavy object handling that requires precise control or continuous operation in complex environments, HD electric hoist overhead crane can provide stable and reliable lifting solutions.

Freestanding Workstation Overhead Crane

Workstation overhead crane, no special modification to the factory; flexible installation; convenient disassembly.

The 1-ton stand-alone workstation overhead crane is a lifting equipment designed for small working environments. It combines the stability of a overhead crane with the flexibility of a stand-alone workstation, providing users with efficient and safe lifting solutions.

The main feature of this crane is its stand-alone workstation design, which means that it does not need to rely on external structures or supports and can be flexibly deployed as an independent lifting unit in places such as workshops, warehouses or laboratories. This design not only saves space, but also improves the flexibility and adaptability of the crane, enabling it to easily cope with various complex lifting operations.

In terms of lifting capacity, the 1-ton stand-alone workstation overhead crane has a strong carrying capacity and can easily lift and carry cargo weighing up to 1 ton. Its lifting mechanism adopts advanced electric hoists, which are driven by electric motors to achieve smooth lifting and lowering of cargo, ensuring the efficiency and safety of lifting operations.

In addition, the crane is also equipped with a complete electrical control system and safety protection devices. The electrical control system adopts advanced control technology to achieve precise control and stable operation of the crane. Safety protection devices include limit switches and overload protection devices, which can cut off the power supply in time when the crane exceeds the working range or is overloaded, ensuring the safety of personnel and goods.

It is worth mentioning that the 1-ton independent workstation overhead crane also has good maintainability and durability. Its compact structure and standardized components make maintenance and replacement of parts more convenient and quick. At the same time, the use of high-quality materials and advanced manufacturing processes ensures the long-term stable operation and long life of the crane.

LB Explosion-proof Single Girder Overhead Crane

The first choice for flammable and explosive environments such as dust, oil and gas.

The 1-ton explosion-proof single-girder overhead crane is a device designed for safe lifting operations in explosive environments. It combines the compactness of the single-girder overhead crane with the safety of explosion-proof technology to ensure reliable operation in high-risk industries such as petroleum, chemical, and coal.

The main feature of this crane is its explosion-proof performance. All its components, including electrical systems, mechanical components, and control systems, have been specially designed to be explosion-proof to ensure that no sparks or high temperatures are generated in explosive gas or steam environments, thereby avoiding explosions. This design enables the 1-ton explosion-proof single-girder overhead crane to be safely used in these high-risk industries for operations such as material handling, assembly, and storage.

In terms of structure, the crane adopts a single-beam structure, and the main beam and the end beam are connected by high-strength bolts to form a stable lifting platform. This design not only reduces the deadweight of the crane, but also improves its load-bearing capacity and stability. At the same time, the crane’s lifting mechanism usually adopts an electric hoist, which has the advantages of small size, light weight, and easy operation, making the crane more efficient and stable during operation.

In terms of safety, the 1-ton explosion-proof single-beam overhead crane is equipped with a variety of safety protection devices, such as limit switches, overload protection devices, etc. These devices can cut off the power supply in time when the crane exceeds the working range or is overloaded, ensuring the safety of personnel and goods.

In addition, the crane also has good maintainability and durability. Its compact structure and standardized components make maintenance and replacement of parts more convenient and quick. At the same time, the use of high-quality materials and advanced manufacturing processes ensures the long-term stable operation and long life of the crane.

| Overhead Bridge crane | Capacity | Span | Height | Coverage Area Type | Coverage Area | Motorization |

| General-purpose Single Girder Overhead Crane | 1 ton | 7.5m to 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes |

| Low Headroom Single Girder Overhead Crane | 1 ton | 7.5m to 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes |

| Single Girder Overhead Crane – European style | 1 ton | 7.5m to 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes |

| Freestanding Workstation Bridge Cranes | 1 ton | 1m to 9m | 1m to 6m | Square/Rectangle | 9m x Unlimited Length | Yes |

| Ceiling-mounted Workstation Bridge Crane | 1 ton | 7.5m to 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes |

| Explosion-proof Single Girder Overhead Crane | 1 ton | 7.5m to 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes |

In the process of customizing a 1 ton overhead crane, we often need to use different spare parts according to the actual use of the customer, which will be more conducive to the customer to play the function of the overhead crane. Below we briefly introduce the main spare parts of the overhead crane, if you have different needs, please feel free to let us know

1-ton bridge crane is suitable for a variety of indoor environments, but the main factors to be considered are the climatic conditions of its working environment, space requirements, and the characteristics of the hoisted items. The following is a detailed analysis of the indoor environment suitable for 1-ton bridge cranes:

Temperature:

Wind pressure:

Track installation:

Height limit:

Width and length:

Weight limit:

Shape and size:

Radiant heat:

Electrical safety:

Maintenance:

Purchase of one 1-ton overhead crane from Pakistan Agricultural Products Processing Plant

In the warehouse, this 1-ton bridge crane is used for lifting, moving, and storing goods, greatly improving the operational efficiency of the warehouse and reducing labor costs.

We are a crane manufacturer located in China, providing crane customization services to global crane customers. If you want to customize a Overhead Crane, you can leave a message on the website or Email: sales010@cranesdq.com, tell us the following information, and our sales manager will contact you:

You can either fill out the contact form or send us an email. After receiving your inquiry, we will contact you as soon as possible and provide you with a suitable offer.

Contact our crane specialists

Send us a message and we will get back to you as soon as possible.