As an indispensable large-scale equipment in industrial production, the performance and safety of 10T gantry cranes are directly related to production efficiency and personnel safety. With the advancement of technology and the change of production processes, it is particularly important to transform and upgrade existing cranes to adapt to new production needs. This construction plan aims to elaborate on the transformation and installation process of 10T gantry cranes, from pre-construction preparation to post-installation inspection and commissioning, and strive to be accurate and correct in every step. We will explore the requirements and safety measures of construction personnel in depth to ensure that every link in the construction process meets high standards and strict requirements. At the same time, site preparation and equipment inspection will lay a solid foundation for transformation and installation, and the whole machine transformation and installation steps are the core of the entire plan. Finally, through strict safety acceptance and construction site cleaning, it is ensured that the transformed crane can be safely and efficiently put into production.

Before officially launching the 10T gantry crane transformation and installation project, careful planning and thorough preparation are required to ensure the smooth progress of the project and its ultimate successful implementation.

The first task is to conduct a comprehensive and detailed evaluation and analysis of the technical status of the existing crane. This includes but is not limited to detailed inspection and testing of the crane’s structural stability, mechanical transmission system, electrical control system, safety protection devices, and lifting capacity. Based on the evaluation results, the project team needs to clarify the goals and specific needs of the transformation, such as improving the efficiency of the crane, increasing its carrying capacity, improving its operating performance, or extending its service life. At the same time, factors such as the crane’s workload, working environment, and expected life should be fully considered to ensure that the transformed equipment can meet future usage needs.

It is crucial to develop a detailed construction plan. The construction plan should include the design of the construction process, the arrangement of time nodes, the procurement and deployment of required materials and equipment, etc., to ensure that all resources are efficiently allocated. The construction process should detail the sequence and connection methods of each transformation link to ensure the continuity and efficiency of the construction process; the time node should clarify the goals and completion time of each stage to facilitate the control and supervision of the project progress; the preparation of the required materials and equipment should fully consider the performance parameters, frequency of use, and actual conditions on site of the equipment to ensure that the supply of materials during the construction process is sufficient and timely.

During the construction process, communication and coordination are essential. The project team needs to maintain close contact with relevant departments and personnel to ensure that the safety management, traffic diversion and environmental protection measures are in place during the construction period. This includes but is not limited to effective communication and collaboration with on-site managers, safety supervisors, traffic management departments and environmental protection departments. At the same time, the construction site should be reasonably planned and laid out, obvious safety warning signs should be set up, and emergency plans should be formulated to deal with possible emergencies to ensure the safety and smooth progress of the construction process.

Pre-construction equipment and environmental checklist (crane renovation and installation project)

| Inspection items | Inspection content | Inspection standards/requirements | Inspection results |

| Equipment structure stability | Structural components such as main beam, outrigger, end beam, etc. | No cracks, deformation, firm connection | _ |

| Mechanical transmission system | Reducer, coupling, bearing, etc. | Flexible operation, no abnormal sound, good lubrication | _ |

| Electrical control system | Motor, cable, control cabinet, etc. | Good insulation, firm wiring, normal function | _ |

| Safety protection device | Limiters, buffers, windproof devices, etc. | Effective function and comply with safety specifications | _ |

| Lifting capacity | Rated crane lifting capacity and working range | Meet the design requirements without overloading | _ |

| Working environment | Ground flatness, bearing capacity, air obstacles | Meet the crane operation requirements and no safety hazards | _ |

| Materials and equipment preparation | Materials, tools, equipment, etc. required for construction | Adequate quantity, good performance, meet construction requirements | _ |

| Construction plan and process | Construction process design, time node arrangement | Clear process, clear time nodes, reasonable resource allocation | _ |

| Communication and coordination | Communication with relevant departments and personnel | Smooth communication, effective collaboration, and perfect emergency plans | _ |

| Site Safety Layout | Safety warning signs, emergency channels, etc. | Reasonable setting and comply with safety specifications | _ |

Details of environmental and safety inspections before construction

| Check Category | Checkpoint | Check details | Check results |

| Site Conditions | Ground conditions | Flat and pothole-free, bearing capacity meets requirements | _ |

| Aerial obstacles | Wires, pipes, etc. that do not affect crane operations | _ | |

| Environmental factors | Wind direction and speed | Record the current wind direction and wind speed to ensure operation safety | _ |

| Lighting conditions | The construction site is well-lit and there are no blind spots of lighting | _ | |

| Safety warning | Warning sign | Set up obvious safety warning signs to remind workers | _ |

| Emergency preparation | Emergency plan | Formulate emergency plans and clarify emergency measures and persons responsible | _ |

| Emergency equipment | Equipped with fire-fighting equipment, first aid kit and other emergency equipment, and regularly inspected | _ | |

| Personnel training | Safety Education | Safety education and skills training for workers | _ |

| Special operation certificate | Special operations personnel hold valid certificates to work | _ | |

| Traffic Management | Construction area division | Plan the construction area reasonably and set up fences and warning lights | _ |

| Traffic guidance | Formulate traffic diversion plans to ensure smooth traffic during construction | _ |

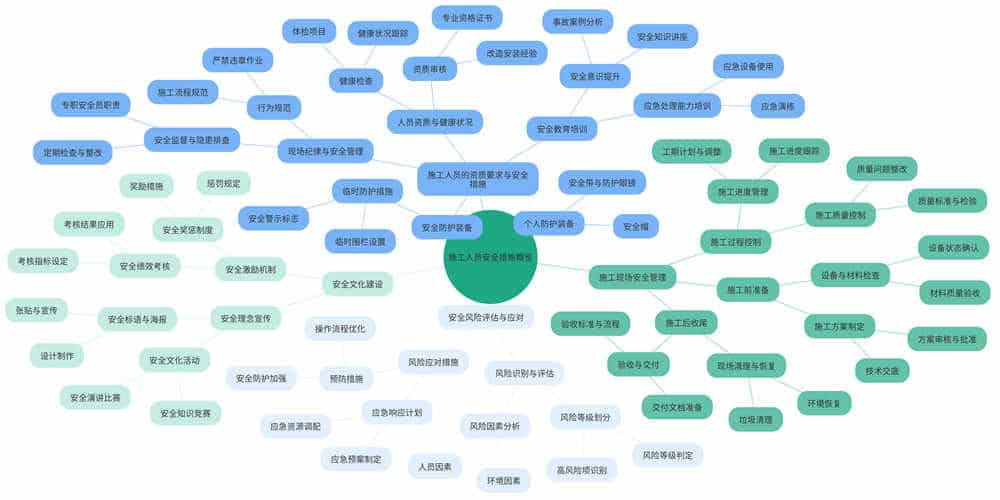

In the renovation and installation project, construction personnel are the core factor for the success of the project. To ensure the quality and safety of the project, all personnel involved in the construction must have the corresponding professional qualification certificates and have rich experience in crane renovation and installation. Before the formal construction, all construction personnel will undergo a strict health check to ensure that they have no health problems that affect construction safety. In addition, targeted safety education and training will be carried out to enhance the safety awareness of construction personnel and teach emergency response capabilities.

To ensure construction safety, a complete set of safety protection measures will be set up on site. Including but not limited to setting up safety warning signs, equipping necessary personal protective equipment (such as safety helmets, safety belts, protective glasses, etc.), installing temporary fences, etc. These measures will effectively remind construction personnel to pay attention to safety and prevent accidents. At the same time, strict on-site discipline will be formulated, the behavioral norms of construction personnel will be clarified, and illegal operations will be strictly prohibited. A full-time safety officer will be set up to be responsible for on-site safety supervision and hidden danger investigation to ensure that construction safety is always under control. The safety officer will conduct regular inspections on the site to promptly discover and eliminate safety hazards to ensure the safety of construction personnel and the smooth progress of the project.

The reasonable arrangement of equipment and tools is the basis for efficient construction. Before construction, all equipment entering the site needs to be comprehensively and carefully counted and inspected. First of all, it is necessary to ensure that the performance of all equipment is good, including but not limited to the working efficiency, stability, safety and other aspects of the equipment. For tool equipment, it is also necessary to check whether its quantity is sufficient and whether it is suitable for the upcoming construction project.

According to the construction plan and the actual situation on site, formulate reasonable equipment and tool entry routes and layout locations. When planning the entry route, the size, weight and road conditions of the equipment on site should be fully considered to ensure that the equipment can enter the site smoothly and reach the designated location. In the selection of the layout location, it is necessary to ensure that the construction area is unobstructed and easy to operate and dispatch. At the same time, the maintenance and maintenance needs of the equipment should also be considered to ensure that the equipment can be maintained and supported in time during use.

A detailed appearance and quality inspection of the crane is a prerequisite for ensuring the quality of the renovation and installation. The inspection content covers the overall structure, welds, bolt connections and other parts of the crane to ensure that there is no obvious damage or deformation. During the inspection, it is necessary to carefully check the various components of the crane, including the metal structure, mechanical transmission part, electrical control system, etc., to ensure that they are intact. At the same time, the key components are tested for material quality, including the chemical composition and mechanical properties of the metal materials, to ensure that they meet the design requirements and industry standards.

According to the actual situation on site, the construction location should be reasonably selected, and a suitable construction location should be selected before construction. This location needs to ensure that the crane can move and position smoothly and safely during the installation process. When selecting the construction location, factors such as the terrain, landform and meteorological conditions of the site need to be considered to ensure the safety and smooth progress of the construction.

Before construction, the power supply of the crane must be cut off and a “no closing” warning sign must be hung. This is to prevent safety accidents caused by accidental power on. At the same time, it is also necessary to ensure that the construction site is always kept clean and orderly during the construction process to avoid accidents caused by debris or obstacles.

Lifting and connection of main beam and outrigger is the first step in whole machine transformation and installation, and it is also the most critical part of the whole transformation process. During the lifting process, professional lifting equipment and technology will be used to ensure a smooth and safe lifting process. Before lifting, it is necessary to accurately calculate and mark the lifting points to ensure balanced force during the lifting process and avoid deformation or damage of the main beam and outrigger due to excessive or insufficient force. After lifting, the main beam and outrigger are precisely docked and connected with high-strength bolts to ensure a firm and reliable connection.

As a key component of the crane, the installation quality of the electric hoist directly affects the performance of the crane. During the installation process, the electric hoist is accurately positioned and connected in strict accordance with the design requirements and industry standards. Adjust the running track of the electric hoist to ensure that it runs smoothly and without jamming.

The installation of parts requires meticulous operation to ensure that each part is accurately in place and functions properly. During the installation process, pay attention to the matching clearance and tightening strength between parts to prevent failures or safety hazards caused by improper installation. At the same time, lubricate key parts to reduce friction and wear and extend the service life of the crane.

Electrical installation is an important part of crane modification and installation. The electrical system of the crane will be fully installed and debugged in accordance with the electrical design drawings and industry standards. Including cable laying, electrical component installation, line connection, etc. In addition, the crane is grounded to ensure the safety and reliability of the electrical system. Grounding can effectively avoid problems such as static electricity and electromagnetic interference generated by the electrical system during operation, and can also ensure the safety of the equipment.

In the installation process of the crane, the inspection and tightening of the fastening points are crucial links. After the installation is completed, we will use professional testing tools and methods to conduct a comprehensive and detailed inspection of all fastening points of the crane. We will ensure that each fastening point can meet the design requirements of the tightening force to ensure the overall stability and safety of the crane. During the inspection, if the fastening point is found to be loose or does not meet the requirements, we will deal with it in time to ensure the safe operation of the crane.

After the installation is completed, we will conduct a comprehensive and detailed completeness and effectiveness inspection of all parts on the crane. This will include confirming the installation position, installation method and functional status of each component one by one. Ensure that each component has been correctly installed and functioning properly without missing or damage. For missing or damaged parts found during the inspection, we will promptly supplement or replace them to ensure the integrity and reliability of the crane.

During the whole machine commissioning stage, we will conduct comprehensive and detailed testing and adjustments on various performance indicators of the crane. These tests will include, but are not limited to, key indicators such as the crane’s lifting capacity, operating speed, and braking performance. In addition, we will conduct a trial run test to further confirm the crane’s performance by observing its operating status and stability. During the test, if any problems or abnormalities are found, we will promptly handle and adjust them to ensure that the crane can operate normally and meet design requirements.

Machine commissioning and trial operation checklist (fastening point inspection)

| Serial number | Fastening point position | Design fastening force | Actual fastening force | Inspection results | Handling measures |

| 1 | Main beam connection point | _ | _ | _ | _ |

| 2 | Outrigger connection point | _ | _ | _ | _ |

| 3 | Boom connection point | _ | _ | _ | _ |

| 4 | Motor base connection | _ | _ | _ | _ |

| 5 | Drive shaft connection | _ | _ | _ | _ |

Machine commissioning and trial operation checklist (performance and trial operation test)

| Serial number | Test items | Design requirements | Test results | Description of test results | Handling measures |

| 1 | Lifting capacity | Maximum lifting weight _ tons | _ | _ | _ |

| 2 | Running speed | _ meters/second | _ | _ | _ |

| 3 | Braking performance | Braking distance_meter | _ | _ | _ |

| 4 | Stability test | No significant shaking or tilting | _ | _ | _ |

| 5 | Noise level | _ dB | _ | _ | _ |

| 6 | Electrical system reliability | No fault or abnormality | _ | _ | _ |

Safety acceptance is an important part of ensuring the quality and safety of crane modification and installation projects. In order to achieve this goal, strict safety acceptance standards and procedures will be formulated in accordance with relevant national laws and regulations and industry standards. During the acceptance process, the structure, performance, safety devices and other aspects of the crane will be comprehensively inspected and tested. These inspections include but are not limited to detailed inspections of the structural stability of the crane, the safety of the electrical system, the performance of the hydraulic system, etc. In addition, institutions with professional qualifications will be invited to conduct third-party testing and evaluation. The purpose of this is to ensure that the safety performance of the crane meets the requirements of relevant national laws and regulations and industry standards, and provide strong guarantees for subsequent use.

After the construction is completed, the construction site will be fully cleaned and organized. Including removing garbage, recycling waste materials and equipment, etc. This work not only helps to keep the construction site clean, but also effectively reduces environmental pollution and achieves the goal of green construction. After the construction site is cleaned, the crane will be repainted. The repainting work not only needs to repair the paint damage caused by construction, but also needs to maintain coordination with the surrounding environment. After the repainting is completed, a quality inspection will be carried out to ensure that the repainting effect meets the requirements and improves the appearance and corrosion resistance of the crane.

During the acceptance process, a complete acceptance document will be formed. Including construction plan, construction drawings, test report, acceptance report, etc. These documents not only record important information and details during the crane modification and installation process, but also provide strong reference and support for subsequent use and maintenance. In order to facilitate subsequent inquiries and use, all documents will be sorted and archived. The sorted documents will be archived according to category and date to ensure the integrity and traceability of the documents. In addition, a crane maintenance and maintenance archive will be established to provide strong support for subsequent use and maintenance. The purpose of this is to provide more comprehensive and reliable information and basis for subsequent use and maintenance, and extend the service life of the crane.

Contact our crane specialists

Send us a message and we will get back to you as soon as possible.