As an indispensable and important equipment in modern industry and manufacturing, the 2-ton overhead crane not only greatly improves production efficiency, but also meets the needs of various heavy lifting and handling operations with its unique design and comprehensive functions. In the rapidly developing industrial field, this crane has become a powerful assistant on the production lines of many companies with its powerful lifting capacity, flexible operation and excellent safety performance. From machinery manufacturing to automobile assembly, from logistics warehousing to port terminals, the 2-ton overhead crane has become a beautiful landscape in the development of modern industry with its wide range of applications and outstanding performance.

Below is an overview of price ranges for 2-ton overhead bridge cranes. Please note that these prices are only examples, and actual prices may vary due to factors such as brand, configuration, market supply and demand, transportation costs, installation fees, and specific customization requirements. The prices below are listed in Chinese yuan and also include estimated US dollar prices based on the current exchange rate (assuming 1 USD ≈ 7.2 CNY).

| Span (meters) | Price Range (CNY) | Price Range (USD, estimated at 1 USD ≈ 7.2 CNY) |

|---|---|---|

| 7.5 | Approximately 15,000 to 30,000 yuan | Approximately 2,083 to 4,167 USD |

| 10.5 | Approximately 20,000 to 40,000 yuan | Approximately 2,778 to 5,556 USD |

| 13 | Approximately 25,000 to 50,000 yuan | Approximately 3,472 to 6,944 USD |

| 16.5 | Approximately 30,000 to 60,000 yuan | Approximately 4,167 to 8,333 USD |

| 22.5 | Approximately 40,000 to 80,000 yuan | Approximately 5,556 to 11,111 USD |

Important Notes:

I hope this price list provides you with a certain reference value. If needed, please feel free to contact us or relevant suppliers for further consultation.

Most commonly used small material handling equipment, suitable for most factories, warehouses, etc.

The LD 2-ton single-beam overhead crane is a well-designed and fully functional lifting equipment. It is manufactured in strict accordance with the JB/T1306-94 standard to ensure the safety and rationality of the structure. This crane is used in conjunction with electric hoists such as CD1 and MD1 to form an efficient rail-operated lifting system, which is easy to operate and improves work efficiency.

In terms of technical parameters, the LD 2-ton single-beam overhead crane has a lifting capacity of 2 tons and is suitable for medium-weight lifting and handling operations. Its applicable span range is between 7.5 and 22.5 meters, which can be selected according to the actual work site and needs. In addition, the crane can operate normally at an operating ambient temperature of -25℃ to +40℃, showing its strong environmental adaptability.

In terms of structure, the LD electric single-beam overhead crane adopts a three-beam structure, and the main beam and end beam are connected by high-strength bolts to ensure the stability of the structure. At the same time, buffer blocks are set on both sides of the main beam to prevent collision when the operating mechanism reaches the limit position.

In terms of drive and control, the lifting mechanism of the crane adopts an electric hoist, which is designed and manufactured by a professional manufacturer to ensure the stability and safety of the lifting. The trolley running mechanism adopts four-wheel drive, driven by two conical brake motors, and the number of driving wheels accounts for half of the total number of wheels. This design makes the operation of the trolley more stable and reliable. In terms of control, the operation of each mechanism of the crane is controlled by the ground control button box, which works with the electronic control equipment to achieve precise control of actions such as starting, changing direction, and braking.

In terms of electrical system, the main circuit and control circuit voltage of the ground crane electrical system are 380V and the frequency is 50HZ, which ensures the stability and safety of the electrical system. At the same time, the crane is also equipped with safety protection devices such as limit switches and overload protection devices. When the crane runs to the limit position or overloads, it can automatically cut off the circuit to ensure the safe operation of the crane.

LD 2-ton single-girder overhead crane has been widely used in many industries, such as automobile manufacturing, steel manufacturing and machinery manufacturing, warehouse management, logistics center, building material handling, equipment installation, ore lifting and handling, container loading and unloading, chemical and pharmaceutical industries, etc., due to its strong carrying capacity, high working efficiency and easy operation. These industries cover a wide range of fields, from manufacturing to logistics warehousing, construction, mining, etc., which fully proves the importance and practicality of LD 2-ton single-girder overhead crane in industrial production and construction.

Ldp Low Headroom Single Girder Overhead Crane

It is designed for low-height room, suitable for limited lifting space but high lifting height.

The LDP 2-ton low-headroom single-beam overhead crane is a lifting equipment designed for low spaces, with the characteristics of compact structure, flexible operation and smooth operation. This crane adopts a box-beam structure, and the electric hoist is hung on one side of the main beam. This design not only increases the service space of the hook, but also effectively reduces the requirements for the height and cost of the factory building.

In terms of technical parameters, the LDP 2-ton low-headroom single-beam overhead crane has a rated load of 2 tons, which is suitable for a variety of span requirements, generally between 7.5 meters and 30 meters, and can be selected and customized according to the actual work site. Its lifting height is usually between 6 meters and 12 meters, ensuring sufficient lifting operation space. At the same time, the working level of the crane is A3 or A4, which is suitable for different working environments and operation requirements.

In terms of drive and control, the LDP crane is usually used in conjunction with CD or MD electric hoists to realize the automation and efficiency of lifting operations. There are various control methods, including ground control, remote control operation, etc., which can be selected according to actual needs. In addition, the crane is also equipped with various safety protection devices, such as limit switches, overload protection devices, etc., to ensure the safety and reliability of lifting operations.

LDP 2-ton low-headroom single-beam overhead crane is widely used in lifting operations in factories, warehouses, material yards and other different occasions. Its compact structure and smooth operation enable it to operate flexibly in low spaces, improving work efficiency and space utilization. At the same time, the operation of the crane is simple, safe and reliable, reducing the labor intensity and safety risks of operators.

HD Electric Hoist Overhead Crane

The HD 2-ton electric hoist overhead crane is a new general-purpose crane designed according to European standards. It integrates the modular design concept and has maintenance-free characteristics, providing users with efficient and reliable lifting solutions.

This crane adopts advanced European lifting technology in structural design. Key components such as the main beam and end beam are optimized and designed with light weight and strong rigidity, ensuring the stability and safety of the crane. At the same time, the modular design makes the assembly and maintenance of the crane more convenient. Users can choose appropriate modules to combine according to actual needs to meet different lifting needs.

The electric hoist of the HD 2-ton electric hoist overhead crane is one of its core components. It uses high-quality materials and advanced manufacturing processes to ensure the durability and reliability of the hoist. The hoist has a lifting capacity of 2 tons and is suitable for a variety of lifting operation scenarios. At the same time, the hoist also has the characteristics of vertical anti-sway and low clearance, which improves the stability and efficiency of lifting operations.

In terms of control, this crane provides a variety of control methods, such as ground wired handles, ground wireless remote control, etc., so that operators can control the operation of the crane more conveniently. At the same time, the crane is also equipped with various safety protection devices, such as limit switches, overload protection devices, etc., to ensure the safety of lifting operations.

In addition, the HD 2-ton electric hoist overhead crane also has a wide range of applicability. It can be used for lifting operations in factories, warehouses, material yards and other occasions, meeting the needs of different users. At the same time, this crane also has the characteristics of high efficiency and energy saving. Through optimized design and advanced control technology, it reduces energy consumption and noise, and meets the environmental protection requirements of modern industrial production.

Freestanding Workstation Overhead Crane

Workstation overhead crane, no special modification to the factory; flexible installation; convenient disassembly.

The 2-ton independent workstation overhead crane is a lifting equipment designed for a specific work area. It has the characteristics of an independent workstation and can efficiently complete lifting and handling tasks.

This crane has a compact structure, reasonable design, light weight and strong rigidity, which ensures the stability and safety of the crane. Its lifting capacity reaches 2 tons and is suitable for a variety of lifting operation scenarios, such as machinery manufacturing, automobile manufacturing, hardware manufacturing and other industries. At the same time, the design of the independent workstation allows the crane to be flexibly installed in various workplaces without being hindered by ground equipment, making full use of space resources.

In terms of control, the 2-ton independent workstation overhead crane provides a variety of control methods, such as ground wired handles, ground wireless remote control, etc., so that operators can control the operation of the crane more conveniently. At the same time, the crane is also equipped with various safety protection devices, such as limit switches, overload protection devices, etc., to ensure the safety of lifting operations.

In addition, this crane also has the characteristics of high efficiency and energy saving. Through optimized design and advanced control technology, energy consumption and noise are reduced, which meets the environmental protection requirements of modern industrial production. At the same time, its maintenance cost is relatively low, saving users operating costs.

LB Explosion-proof Single Girder Overhead Crane

The first choice for flammable and explosive environments such as dust, oil and gas.

The 2-ton explosion-proof single-beam overhead crane is a lifting equipment designed for industrial environments with explosion-proof requirements. This crane adopts a single-beam structure, with the characteristics of simple structure, easy operation, safety and reliability, and is particularly suitable for industrial sites with flammable and explosive gases, such as chemical plants, oil depots, coal mines, etc.

Technically, the 2-ton explosion-proof single-beam overhead crane strictly follows the national explosion-proof standards and adopts advanced explosion-proof technology and materials. Its electrical system has been specially treated to operate safely in an explosion-proof environment, effectively preventing explosion accidents caused by electrical sparks or high temperatures. At the same time, the crane’s lifting mechanism, operating mechanism and other key components also adopt explosion-proof design to ensure the explosion-proof performance of the overall equipment.

In terms of lifting capacity, this crane has a lifting capacity of 2 tons, which can meet the lifting needs of various small and medium-sized materials. Its main beam is made of high-quality steel, with high strength, wear resistance, corrosion resistance and other characteristics, ensuring the stability and durability of the crane.

In terms of control, the 2-ton explosion-proof single-beam overhead crane provides a variety of control methods, such as ground wired handles, ground wireless remote control, etc., so that operators can control the operation of the crane more conveniently. At the same time, the crane is also equipped with various safety protection devices, such as limit switches, overload protection devices, etc., to ensure the safety of lifting operations.

In addition, this crane also has the characteristics of easy maintenance and smooth operation. Its compact structure makes it easier for maintenance personnel to carry out daily maintenance and maintenance work. At the same time, the operating mechanism of the crane adopts advanced transmission technology and deceleration devices, making the crane more stable and noiseless during operation.

| Overhead Bridge crane | Capacity | Span | Height | Coverage Area Type | Coverage Area | Motorization |

| General-purpose Single Girder Overhead Crane | 2 ton | 7.5m to 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes |

| Low Headroom Single Girder Overhead Crane | 2 ton | 7.5m to 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes |

| Single Girder Overhead Crane – European style | 2 ton | 7.5m to 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes |

| Freestanding Workstation Bridge Cranes | 2 ton | 1m to 9m | 1m to 6m | Square/Rectangle | 9m x Unlimited Length | Yes |

| Ceiling-mounted Workstation Bridge Crane | 2 ton | 7.5m to 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes |

| Explosion-proof Single Girder Overhead Crane | 2 ton | 7.5m to 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes |

Our 2-ton overhead crane has achieved remarkable sales results in the Pakistani market. This crane is favored by many construction companies and logistics companies in Pakistan for its high efficiency, stability and safety. Through close cooperation with local dealers, we have successfully promoted this crane to many cities and regions in Pakistan.

During the sales process, we focus on communication with customers, understand their actual needs and usage scenarios, and provide them with personalized solutions. At the same time, we also provide customers with preferential prices and flexible payment methods, which further promotes sales volume.

Grab crane for Pakistan cement factory

Overhead cranes have many parameters, and being familiar with these parameters will help you better understand the crane

Refers to the materials that the crane can lift together with the detachable spreaders or attachments such as grabs, electric

The sum of the masses of magnetic chucks, balance beams, etc.

Refers to the materials that the crane can lift together with the separable spreaders and long-term fixed in the lifting

On-board spreaders and rigs (including hooks, pulley blocks, hoisting wire ropes and

The sum of the mass of other lifting objects below the lifting trolley).

The effective lifting capacity is the net mass of the material that the crane can lift.

1. Span refers to the horizontal distance between the centerlines of the running rails of bridge cranes, and the unit is m. The span of the bridge crane is 1.5-2.0m smaller than that of the workshop (1.5m below 50t).

2. The distance between the centerlines of the trolley running track of the bridge type crane is called the track gauge of the trolley.

3. The distance between the centerlines of the running rails of a jib crane running on the ground is called the gauge of the crane.

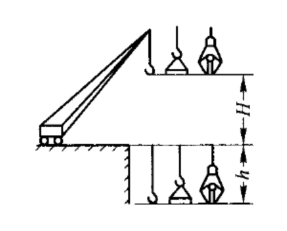

1. The vertical distance from the ground to the highest allowable position of the spreader is marked with H.

2. If the hook can be placed below the ground, the height below the ground is called the descending depth (h).

We are a crane manufacturer located in China, providing crane customization services to global crane customers. If you want to customize a Overhead Crane, you can leave a message on the website or Email: sales010@cranesdq.com, tell us the following information, and our sales manager will contact you:

You can either fill out the contact form or send us an email. After receiving your inquiry, we will contact you as soon as possible and provide you with a suitable offer.

Contact our crane specialists

Send us a message and we will get back to you as soon as possible.