3 ton low headroom wire rope hoist used in Pakistan project construction

In construction projects, customers prefer to buy lifting equipment with stable working performance. In construction site, convenience and ease of use is the best way to improve efficiency. The European standard low headroom wire rope hoist is a very good lifting equipment suitable for this kind of work scene. Today we share a case of a European standard low headroom wire rope hoist from Pakistan.

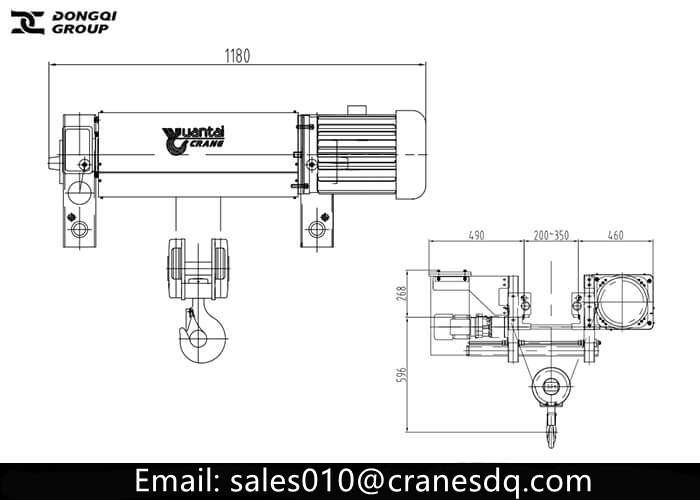

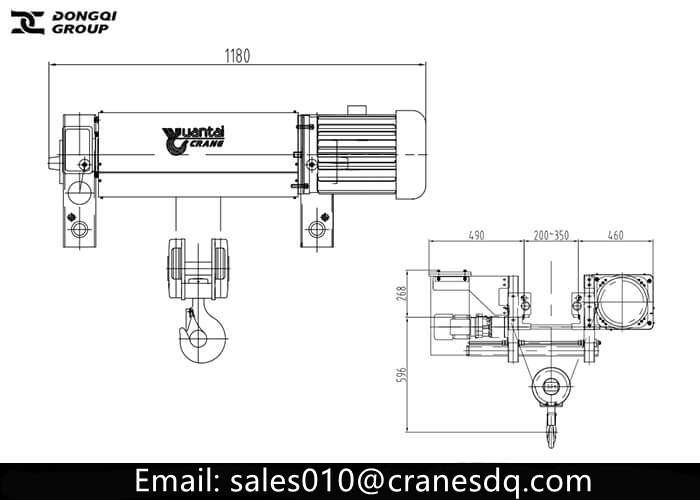

Main parameters of low headroom wire rope hoist in Pakistan

- Type: European standard wire rope hoist

- Lifting capacity: 3 ton

- Lifting height: 10 meters

- Power supply: 380V/3Phase/50HZ

- Application: Construction project

- Working duty: A6

- Lifting speed: 10 m/min

- Travelling speed: 8.0-10 m/min

- Hoisting speed: 0.6/4.0m/min-1.6/10m/min

- Control model: Handle operation remote control

Advantages of European standard wire rope hoist in construction projects

- The low headroom hoist adopts modular manufacturing process, strong versatility, high maintenance-free rate and less wearing parts.

- Compact design scheme to ensure safe operation, convenient and efficient, reasonable structure, simple operation and convenient maintenance.

- The European standard electric hoist has light weight, low headroom, excellent configuration, high transmission efficiency, low noise, energy saving and environmental protection.

Note: Dongqi accept customized European electric hoist according to your demands.

Design details of European standard wire rope hoist accessories

Lifting motor:

- Squirrel cage, double winding 4:1 variable pole two-speed motor.

- Protection class IP55, insulation class F.

- Continuity of power supply 60% ED.

- Built-in thermistor overheat protection, optimized air-cooled.

- Fully sealed drum.

- The motor case is stamped from aluminum tube.

Gearbox:

- Fully sealed compact gearbox.

- Gear material is chromium molybdenum nickel alloy, anti-wear bearings.

- CNC Automatic gear machining center production, hardened surface (HRC60), after grinding treatment.

- Semi-grease lubrication, maintenance-free.

Brake:

- Electromagnetic disc self-adjusting brake, brake pads wear automatically compensation, when the brake pad thickness is not enough, it will have a alarm.

- Normally use of brake pads life should not less than 100 million times, emergency braking is not less than 500 times.

- Normally closed design, when it is power off, the lifting mechanism is out of the braking state.

- To ensure safe dust, no asbestos friction plate friction contact area, brake torque adjustable, good heat dissipation.

Limit switch:

- Cam rotary limit switch 4 fully adjustable upper and lower limits.

- Position accuracy, phase sequence control, first deceleration after the stop. Deceleration operation to improve the brake life and safety.

Drum:

- Extra large reel diameter to extend the life of wire rope, heavy objects placed in a small wire rope with a fixture fixed, at least 2 turns of steel wire rope is fixed fixed bearings made of seamless steel pipe, and processing of high-strength galvanized rope rope rope.

Rope guide:

- High strength nylon rope guide, self-lubricating, small wear on the rope, long life, toughness and flexibility.

- High reliability and easy dis-assembly.

- Even if the hook is reduced to the ground can also keep the rope tension.

Coupling:

- Gear coupling, material Fe52.

Hook:

- Hooks made of large diameter ductile iron pulley and hooks made of anti-wear roller bearings.

- Hook can be rotated 360 degrees.

- Equipped with spring compression of the safety buckle, can prevent slippage.

- Hook forging steel for the modified steel 34CrMoV, T level, according to the standard DIN17200.

[xyz-ihs snippet=”Electric-wire-rope-hoist-cases-in-Pakistan”]