In the crane industry, there are 4 common control methods:

1. Pendent line control

2. Wireless remote control

3. Joystick remote control

4. Cabin control

Below we introduce these four control methods in detail.

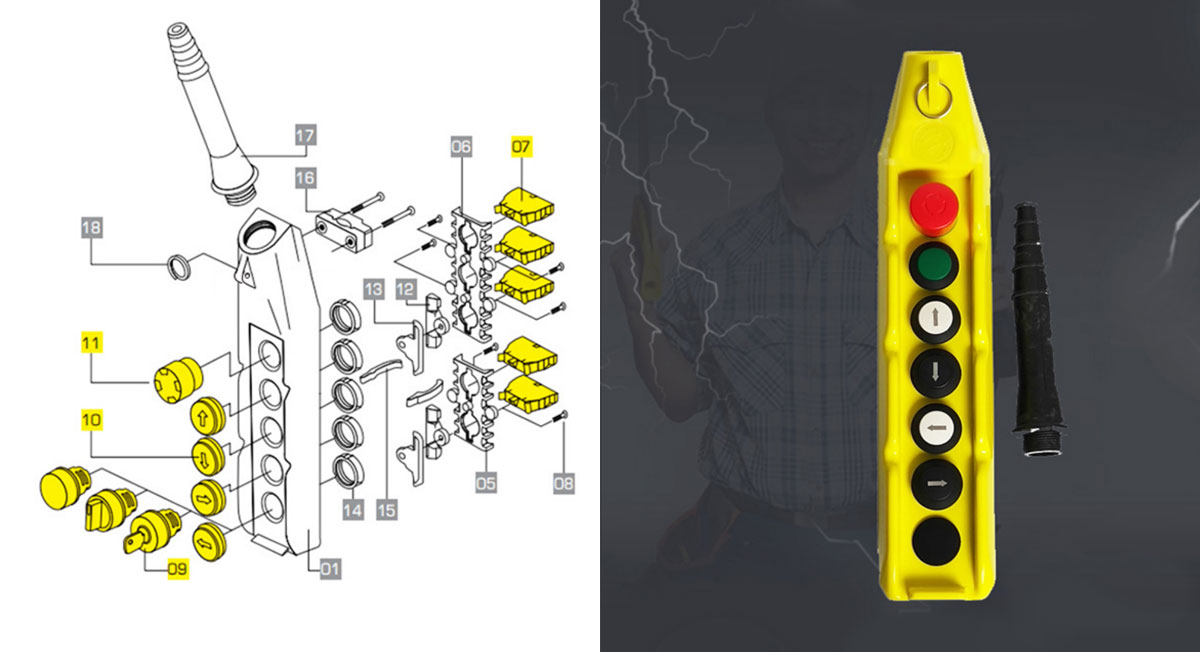

1.Pendent line control

This kind of remote control is generally mainly used in a single mechanism of the hoist, generally four main mechanisms for up and down lifting and left and right running. Simple control structure, it is the default configuration of the hoist remote control

Advantages: waterproof and dustproof, protection grade IP65

Disadvantages: simple structure, only suitable for hoist mechanism

2. Wireless remote control

A remote control is a device that uses radio transmission to perform remote operation control or remote control of industrial machinery. It is composed of a handheld or waist-mounted transmitter and a receiving device fixedly installed on the equipment. The operator mouses people's operation instructions into the transmitter through the operation panel of the transmitter, and then the transmitter digitizes the instructions (coding, After encryption, it is transmitted to the remote receiving system in a wireless way, and the receiving system restores the control instructions after decoding and conversion, so as to realize the control of various mechanical equipment.

This remote control is suitable for crane control in most cases. The wireless design makes the operation easier and more convenient. It can receive clear signals within 100 meters.

With receiver total stop indicator

When working, the indicator light is on to make the operation more intuitive

The back of the receiver is equipped with a shock-absorbing rubber pad, which is easy to install and fix and avoid vibration

Advantages: strong operability, convenient operation, high accuracy, sensitivity, signal continuity, anti-interference, remote control distance, waterproof and dustproof, high and low temperature resistance,

Disadvantages: relatively high cost, not suitable for complex institutions

3. Joystick remote control

Suitable for complex designed crane mechanisms,

The following features can make the remote control transmission system shut down quickly in some specific emergency situations, so as to avoid possible misoperation

1. Impact shutdown function

When the launch system is impacted by the outside world, such as being hit by a heavy object, the launch system will automatically shut down.

2. Rolling shutdown function

When the rollover of the launch system is automatically detected, the launch system is automatically shut down immediately to prevent possible misoperations when the launch system rolls down.

3. Weightless shutdown function

When it is automatically detected that the launch system is in a weightless state, the launch system automatically shuts down immediately. For example, in the event of an inadvertent drop of the launch system or when an operator throws the launch system to another operator, to prevent misoperation that may occur when the launch system is dropped.

Advantages: strong compatibility, suitable for complex design institutions, high accuracy

Disadvantages: high price, difficult design scheme

4. Cabin control

Cabin is an important part of lifting and transportation machinery to ensure the safe operation of drivers. It is widely used in container cranes, ship unloaders, tire port gantry cranes, floating cranes, quayside container gantry cranes, ship loaders, Metallurgical bridge cranes, general bridge cranes and tower cranes and other lifting and transportation machinery.

The Cabin controller uses the low-voltage electrical appliances of the control circuit to indirectly control the electrical equipment of the main circuit, and the quality of its action directly affects the smooth operation of the locomotive and the realization of various working conditions.

Advantages: The field of vision is wide, which is helpful for the operator to see farther, so that the hoisting can find problems in advance and avoid accidents. Especially when lifting larger objects or dangerous goods, the operator will not be affected by the line of sight

Disadvantages: maintenance is complicated; if there is a special person to operate, it also needs a special person to cooperate with hoisting and command, which wastes manpower!