With the continuous growth of global trade, the size and cargo capacity of container ships are increasing. In order to adapt to this trend, the construction of container terminals has gradually developed towards large-scale, deep-water and high-efficiency. In this context, the selection of specifications and parameters of RTG (Rubber tired container gantry crane), which is a special loading and unloading equipment for container terminal yards, is particularly important.

In recent years, in order to improve the loading and unloading efficiency of ports, various terminals have continuously pursued high-speed in the selection of RTG specifications and parameters, such as lifting speed, trolley speed and other key parameters have been improved. However, this high-speed development has also brought new problems:

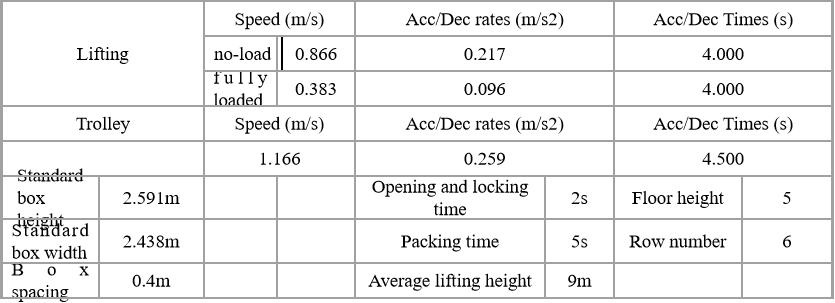

In order to more scientifically evaluate the efficiency of RTG in yard operations, we have designed a dedicated simulation software. Based on advanced algorithms and models, this software can simulate the operation of RTG in different operating scenarios, so as to accurately calculate its operating efficiency. The core functions of the software include:

RTG efficiency calculation (ideal state – smooth loading and unloading)

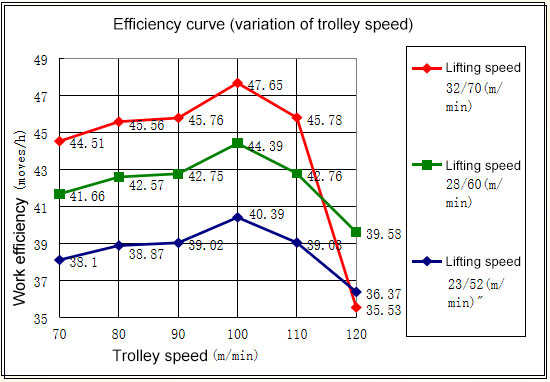

In the operating efficiency of RTG, lifting speed and trolley speed are two crucial technical parameters. In order to gain a deeper understanding of the impact of these two parameters on efficiency, we conducted the following analysis:

Using the efficiency calculation software designed by us, we simulated and analyzed the RTG operating efficiency under different lifting speeds and trolley speeds. The results show:

In order to more intuitively understand the efficiency performance of RTG in actual yard operation, we selected four representative operation cases for analysis, which cover different operation types such as loading and receiving containers.

Operation description: A large container ship needs to load a large amount of cargo, and RTG is responsible for moving the containers on the yard to the ship deck.

Operation time: lasts for 12 hours.

Efficiency performance: During the operation, RTG completes the loading and unloading of 18 containers per hour on average. However, due to the common waiting situation (such as waiting for containers to arrive, waiting for ship deck space, etc.), the actual operation efficiency is lower than the theoretical expectation.

Operation description: A large number of containers arriving at the port need to be unloaded and stacked on the yard, and RTG is responsible for the handling work in this process.

Operation time: lasts for 8 hours.

Efficiency performance: RTG completes the unloading and stacking of 20 containers per hour on average. However, due to the complex layout of the yard, RTG spent a lot of time looking for a suitable stacking location, resulting in a decrease in actual operation efficiency.

Operation description: RTG needs to handle both ship loading and container collection operations in the same time period.

Operation time: 10 hours.

Efficiency performance: In the mixed operation mode, the average operation efficiency of RTG is greatly affected, and only 15 containers are loaded and unloaded per hour. This is mainly due to the increase in operation switching and waiting time.

Operation description: In order to make full use of time resources, the terminal arranges RTG to operate at night.

Operation time: 6 hours.

Efficiency performance: Although the night operation environment is relatively quiet, the average operation efficiency of RTG has not been significantly improved, and 17 containers are loaded and unloaded per hour. This is mainly due to factors such as limited lighting conditions at night and operator fatigue.

By comparing the actual operation efficiency with the theoretical operation efficiency, we found that the actual operation efficiency is generally lower than the theoretical expectation. This is mainly due to the widespread existence of waiting time, including waiting for containers to arrive, waiting for ship deck space, finding a suitable stacking location, and operation switching. These factors have led to the waste of time of RTG during the operation process, thereby reducing the actual operation efficiency.

RTG (Rubber tired container gantry crane) is the main mechanical equipment for container terminal yard operations, which has a vital impact on the overall operating efficiency of the terminal. It is the key equipment for fast and efficient loading, unloading and stacking of containers, and is directly related to the throughput capacity and service quality of the terminal.

However, the operating efficiency of the container terminal is not only determined by the performance of RTG, but also affected by multiple factors. These factors include but are not limited to:

In container terminal yard operations, the parameter selection of RTG (Rubber tired container gantry crane) is crucial to the balance between operating efficiency and cost. By reasonably reducing some key parameters of the RTG, such as lifting speed and trolley speed, it is possible to effectively reduce equipment purchase costs, fuel consumption, and maintenance costs while ensuring that operating efficiency is maintained at an acceptable level.

Appropriately reducing the parameters of RTG not only helps reduce direct costs, such as fuel consumption and maintenance costs, but also indirectly reduces operation interruption and repair costs caused by equipment failure by improving the stability and durability of the equipment. The combined effect of these measures can significantly improve the economic benefits of terminal production and enable the terminal to maintain its advantage in fierce market competition.

In the future, further research is needed on the reasonable parameter range of RTG economic operation to balance operating efficiency and cost. This can be achieved through more actual test data and simulation analysis. At the same time, artificial intelligence technology can also be considered to be introduced into the operation scheduling and optimization of RTG to further improve the loading and unloading efficiency and economic benefits of the terminal.

Contact our crane specialists

Send us a message and we will get back to you as soon as possible.