Dongqi Crane's product line includes various types of cranes, such as electric hoists, bridge cranes, and gantry cranes. These cranes have been carefully designed and manufactured, with excellent performance and quality. Our professional team strictly controls the quality of each type of equipment to ensure that they achieve the highest work efficiency after delivery to customers. In addition, our crane also has the advantages of compact structure, simple operation, and convenient maintenance, which can meet the needs of different industries and fields.

In the Philippines, our sales network covers various industries. From infrastructure construction to manufacturing, from electricity and energy to agriculture and mining, we can find the presence of Dongqi's lifting equipment. In order to meet the needs of different customers, we have also launched customized services for the Philippine market, including equipment customization, installation and debugging, maintenance, etc. These customized services have been widely praised for effectively improving customer production efficiency and equipment lifespan.

Dongqi Crane's corporate culture is based on innovation, quality, and service. Our mission is to provide the highest quality lifting equipment and services to help customers achieve their industrial goals. Our vision is to become a leader in the crane industry in the Philippines and even globally, winning the trust of customers with excellent product quality and thoughtful service. We believe that only by continuously innovating and improving product quality can enterprises remain invincible in the fierce market competition.

LH Double Girder Hoist Overhead Crane has the characteristics as compact instructure, low building clearance light body, and small wheel loading. It can maximize lifting height to make full use of workshop.The speed can be adujisted to be stable travelling.

The application of LH double-beam hoist bridge crane in the Philippines is mainly reflected in many aspects. The following is a detailed analysis:

Industrial field:

LH double-beam bridge crane is widely used in industrial production in the Philippines due to its strong carrying capacity and stable operation. It can be used to lift heavy goods such as steel, mechanical parts, etc., and plays an important role in production lines, assembly lines and warehouses.

Construction field:

On construction sites in the Philippines, LH double-beam bridge cranes are used to lift construction materials such as steel bars, prefabricated concrete parts, etc., which improves construction efficiency and reduces labor intensity.

Ports and logistics:

Ports are one of the important application areas of LH double-beam bridge cranes. In ports in the Philippines, this type of crane can be used to load and unload goods, including containers, bulk cargo, etc., which improves the port's operating efficiency and cargo handling capacity.

Training project at the University of the Philippines: It is reported that Henan Dongqi Machinery Co., Ltd. once exported a 30-ton LH double-beam bridge crane to the University of the Philippines for training on the use of turbine engines. This case shows that the LH double-beam bridge crane is also used in the fields of education and scientific research in the Philippines, especially in projects that require heavy lifting equipment.

Strong carrying capacity: The LH double-beam bridge crane adopts a double-beam structure, which can withstand larger loads and meet various heavy lifting needs.

Smooth operation: The motor drives the reducer to drive the drum to rotate, realize the retraction and release of the wire rope and the lifting and lowering of the goods. The whole process runs smoothly, reducing the risk of damage to the goods.

Convenient operation: The crane is usually equipped with a professional electrical control system, including control circuits, motors, reducers, etc., so that the operator can easily control the operation of the equipment.

Safe and reliable: The design of the double-beam structure improves the safety of the equipment, and the equipment maintenance is relatively simple. By regularly checking the wear of key components and replacing damaged components in time, the long-term stable operation of the equipment can be ensured.

With the continuous advancement of infrastructure construction and industrial development in the Philippines, the application prospects of the LH double-beam hoist bridge crane will be broader. In the future, this type of crane is expected to be used in more fields, such as energy, transportation, chemical industry, etc., contributing to the economic development of the Philippines.

QDX European double girder hoist bridge crane adopts unique European standard design concept, featuring small size, light weight and small wheel pressure.

Although there are no direct cases or detailed reports on the application of QDX double-beam hoist bridge crane in the Philippines, we can speculate on its possible application scenarios and advantages based on the characteristics, performance and needs of related industries in the Philippines.

Industrial manufacturing:

Infrastructure construction:

Logistics warehousing:

Strong carrying capacity:

Smooth operation:

Flexible operation:

Energy saving and environmental protection:

With the continuous development of the Philippine economy and the continuous advancement of infrastructure construction, the demand for efficient, stable and reliable lifting equipment will continue to increase. QDX double-beam hoist bridge crane is expected to gain wider application and recognition in the Philippine market with its superior performance and wide application fields. At the same time, with the advancement of technology and market competition, this type of crane will continue to upgrade and improve to better meet user needs.

It should be noted that since the specific application cases and data may vary due to factors such as time and place, the above content is only speculation and analysis. For more specific information, it is recommended to contact us directly

HD single girder overhead crane has light weight, compact structure and low energy consumption.

The application of HD single-beam electric hoist crane in the Philippines can be analyzed from the following aspects:

Industrial field:

Infrastructure construction:

Warehousing and logistics:

Simple structure:

Easy installation and maintenance:

Efficient handling:

Personalized customization:

Single girder hoist overhead crane is used with CD1 type and MD1 type electric hoist.

The application of LDA single-beam hoist bridge crane in the Philippines can be summarized from the following aspects:

As a light and small crane, LDA electric single-beam bridge crane has the advantages of compact appearance, light weight, small wheel pressure, stable running speed, low noise, and easy installation and maintenance. These characteristics make it very suitable for equipment repair and hoisting operations in warehouses, workshops, power stations and other places. In the Philippines, with the continuous advancement of industrialization and infrastructure construction, the application demand of LDA single-beam hoist bridge crane is also gradually increasing.

LDA single-beam hoist bridge crane has a wide range of applications in many fields in the Philippines, including but not limited to:

Single Girder Gantry crane is matched with CD1 or MD1 electric hoist, and is a light small crane with rail travelling.

The application of MH single-beam hoist gantry crane in the Philippines can be analyzed from the following aspects:

MH single-beam hoist gantry crane is a small and medium-sized simple gantry crane with cantilever, which has the characteristics of compact structure, easy installation and flexible use. It is usually used in conjunction with CD1 and MD1 electric hoists, and is suitable for fixed spans in open-air operations, such as factories, railway freight yards, port terminals, hydropower stations and other places. In addition, the machine has a high working level and various operating methods. Users can choose ground operation or operation room operation according to actual needs. At the same time, it can also be made into a single-end cantilever or non-cantilever structure according to user requirements to meet the needs of different occasions.

In the Philippines, with the rapid development of industrialization and infrastructure construction, the application demand of MH single-beam hoist gantry crane has gradually increased. Its main application areas include:

As a developing country, the Philippines' construction machinery equipment market has maintained a steady growth trend in recent years. With the Philippine government's emphasis on infrastructure construction and industrialization, and the increase in private sector investment in manufacturing and logistics, the market demand for MH single-beam hoist gantry cranes is expected to expand further.

In addition, the price competition in the construction machinery market in the Philippines is relatively fierce, but the products of Asian suppliers are more popular because of their relatively low prices and short delivery time. Therefore, MH crane manufacturers in Asian countries such as China have greater competitive advantages and development potential in the Philippine market.

This type gantry crane is widely used in warehousing and logistics, precision machining, metal fabrication, wind power, automobile manufacturing, rail transportation, construction machinery,

Heavy-duty double-girder gantry cranes are widely used in the Philippines, mainly due to the rapid development of the Philippines in infrastructure construction, manufacturing and resource development. The following is a detailed analysis of the application of heavy-duty double-girder gantry cranes in the Philippines:

Infrastructure construction:

Manufacturing:

Resource development:

Strong lifting capacity:

Good stability:

Strong adaptability:

With the continuous development of the Philippine economy and the continuous advancement of infrastructure construction, the market demand for heavy-duty double-beam gantry cranes will continue to grow. At the same time, with the continuous advancement of technology and the continuous upgrading of products, the performance and functions of heavy-duty double-beam gantry cranes will be further improved and improved. This will provide more efficient and reliable lifting equipment support for the engineering construction and manufacturing industries in the Philippines.

Dongqi supply the single girder crane with lifting capacity: 1~20t, span:7.5~28.5m, lifting height 1~30m, low work class A3,A4. We also design and manufacture the nonstandard crane according users’ demanding.

This crane is used in ambient temperature of -25℃~+40℃,humidity≤85%,elevation under 1000m,power supply is 3-ph, 380V,50HZ(can change as user demand).

QC Electromagnetic overhead crane is a kind of material handling equipment, equipped with detachable electromagnetic chuck and corresponding operating system to handle and lift metal objects. The lifting capacity of the electromagnetic overhead crane included the weight of electromagnetic is 5 to 32 ton. The working class of electromagnetic crane is A5 and A6. The magnetic retentive time is 10 to 30 minutes.

Our company produce gantry crane series with electric hoist mainly with the lifting capacity of 3-16t, span 12-30m, the lifting height of 12-30m, and the light (A3/A4) working duty, also can design and manufacture non-standard series hoist according to your demands.

This gantry crane is used in ambient temperature of -25℃~+40℃,humidity≤85%,elevation under 1000m; the average temperature does not exceed +35℃ within 24 hours, when the average temperature exceeds +25℃, relative humidity allowed temporarily up to 100% within 24 hours, in the temperature of +40℃, relative humidity not more than 50%.suitable power supply is 3-ph, 380V, 50HZ (can change as user demand).

Double girder gantry crane is heavy gantry crane with double girders, which is widely used for general purpose. Double girder gantry crane are heavy duty crane, used at indoors and outdoors places where overhead crane runways are not practical. The lifting capacity of the double girder gantry crane is 5 to 500 tons. The working class of the gantry crane is A5 and A6.

The main parameters of double girder gantry crane are as follow:

| Product Type | MG |

|---|---|

| Lifting Capacity | 5~500t |

| Span Length | 12~35m |

| Working Class | A5, A6 |

| Ambient Temperature | -25~40℃ |

A Semi Gantry Single/Double Girder crane is used in applications such as a tool room where part utilization of the bay is required, or in outdoor sites where a gantry rail can be installed beside an existing structure.

A-frame gantry cranes, also known as A-frame cranes or light duty gantry cranes are suitable for a range of applications. Typically these are small portal gantry cranes for lighter duty lifting requirements. Fitted with the heavy duty castor wheels, the cranes can be effortlessly moved around the workplace and locked in place when required. These cranes are ideal for assembly lines, workshops, service bays and temporary locations.

Simple mobile gantry crane is manufactured for lifting equipment, loading and unloading of the warehouse, maintaining heavy-duty equipment and transporting materials, applicable for small and medium factory. The best advantage of the crane is omni-directional movability, fast to assembly, small volume, can be moved to another are only with a minicar. Capacity is 0.25t-10t, span is 12m. Brake bearing universal wheel can move on the ground, be used together wit electric hoist, chain block, monorail trolley, realizing crane mechanization, which can reduce the human power,production costs, and improve work efficiency.

Portable Jib Crane (also called Mobile Jib Crane / Mobile Cantilever Crane / Movable Jib Crane) is a lifting machine that use electric chain hoist (or electric wire rope hoist) as lifting mechanism and run in any direction to the desired location. The electric hoist can run on the cantilever, suitable for the occasion that the heavy objects need to be moved.

Mobile cantilever crane with flexible mobility, wide adaptability and other characteristics, is an efficient automatic production line on the necessary emergency emergency lifting equipment, with it to ensure that the production line unimpeded. The jib crane widely used in factories and mines, workshops, field, warehouse installation of small equipment, cargo and workpiece handling, and low construction should not be set up driving and other places.

Wall travelling jib crane is a cost effective crane which travels along the rail mounted on the wall or other supported structure on elevated orbit of a multilayer assembly shop, making the full advantages of the working space. Wall travelling jib crane can provide long lateral movement of materials and at the same time can lift the objects in the vertical direction by the lifting equipment. The lifting capacity of wall travelling jib crane is 0.5 to 10 tons and working class is A3

Wall travelling jib crane is an optimal solution for material handling, used in workshop of machine manufacturing and assembling, etc. It also can be used as a complement to an overhead crane system to do material handling working efficiently. A wall travelling jib crane offers a good solution for handling materials at workstation.

Pillar jib crane also called pillar mounted jib crane is a type of freestanding small and medium material handling equipment with the base plate installed on the floor without any support from the building. The lifting capacity of pillar jib crane is 0.5 to 10 tons and the working class is A3.

Pillar jib crane is widely used in workshop, warehouse, dock, yard, storage and other places where the pillar can be installed. Pillar jib crane shows superiority when used in short range or serried applications.However, they are forbidden to be used in dangerous applications where is inflammable, explosive, and corrosive, etc. What’s more, pillar jib crane cannot be used to handling molten metal, toxic and inflammable and explosive materials, etc.

The wall mounted jib crane can be a tie-rod jib crane, which has a tie-rod mounted to the structure of your building, without taking any of your square feet of your plant. The wall mounted jib crane is the most economical crane for material handling. The lifting capacity of the wall mounted jib crane is 0.25 to 1 ton and the working class is A3.

Wall mounted jib crane is usually applicable to short distance, frequent and intensive material handling operations, in the places, such as, workshops, warehouses, docks, storage, ports, and assembly line, etc.

Double speed electric hoist is a small-sized lifting equipment, which is installed on the single girder, bridge cranes, gantry cranes, jib cranes for material handling. As one of the commonly used material handling equipment, the double speed electric hoist is usually used in factory, mining, railway, port, and storage, etc.

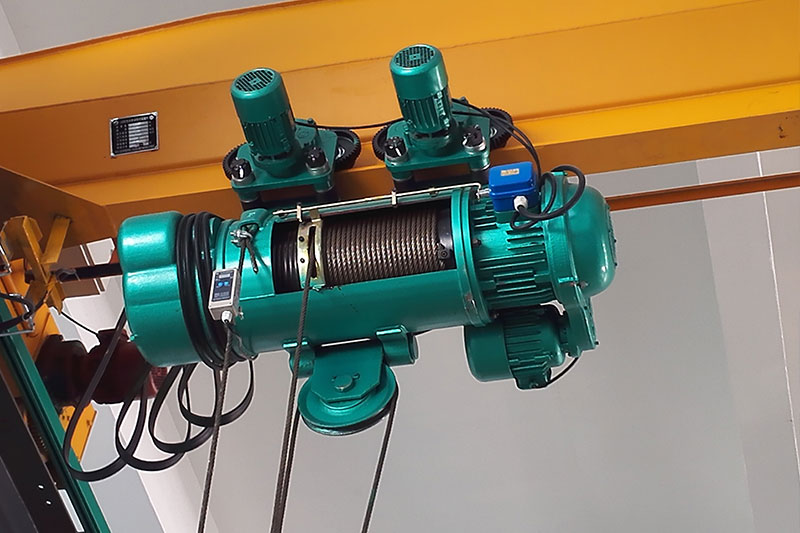

Electric wire rope hoist is a type of material handling equipment, installed on a single beam crane, linear curve strander beams or it can be used at the hoisting mechanism of double beam crane, gantry crane, linear crane for material handling by industrial and mining enterprises, railways, and warehouses, etc. The lifting capacity of single speed electric wire rope hoist is 0,5 to 32 ton and the working class is M3 and M4

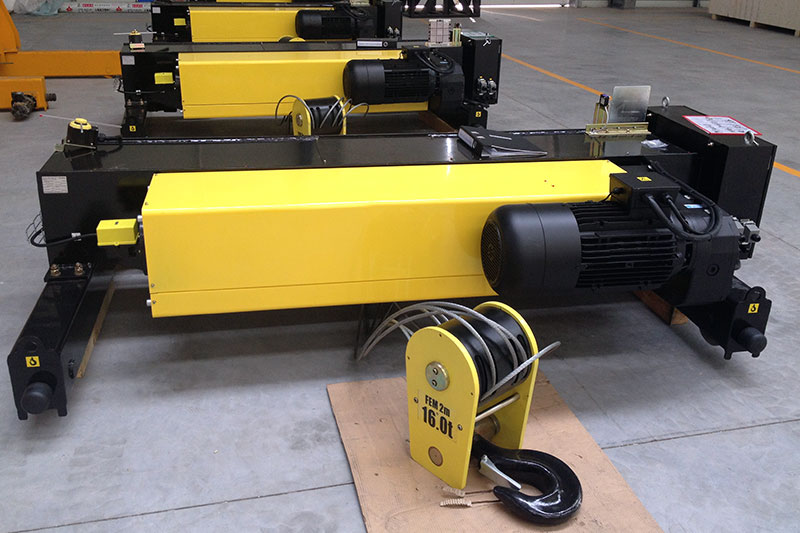

European wire rope electric hoist is a newly developed material handling equipment with advanced design technology according to the FEM standards and other regulations. The new serial of wire rope electric hoist is environment-friendly, energy saving and cost-effective which ranks top among similar products. The lifting capacity of the European wire rope electric hoist is 1 to 80 tons and the working class is M5 and M6. Customized European wire rope electric hoist are available.

Electric chain hoist is a light and small lifting equipment for material handling. Electric chain hoist is mainly consisted of motor, transmission mechanism and chain wheel, etc. Electric chain hoists from DQCRANES have the features of beautiful outlook, solid durability, and international technology, etc. The inside gears of electric chain hoist are hot quenched which increases the wear resistance of the gear and toughness. The lifting capacity of electric chain hoist is 0.5 to 35 ton, and the working class is M3 or M4

Low headroom electric hoist is transformed from CD / MD electric hoist. The product has the characteristics of compact structure, lifting single, double speed, high effective lifting stroke and stable operation. It has wide application range, especially in new factory buildings. The height of the trip can reduce the height of the building and reduce the construction cost.

Manual chain hoist / chain block is one of the most economical material handling equipment with features of hand operation, simple structure, cost-effective, widely application, etc. What’s more, the spark resistant features, such as, stainless steel, bronze hooks, chains, wheels, etc are available to manual chain hoist / chain block. The lifting capacity of manual chain hoist / chain block is 0.5 to 100 ton