Life-time care to your cranes is given by Dongqi crane services. . The crane inspection and crane maintenance services is meant to improve your equipment safety and productivity through a series of preventive inspections, routine maintenance, and corrective maintenance, and modernization service.

The preventive crane inspections is meant to identify risks to prevent crane accidents and breakdown time and identify the chances for improvement of crane performance and safety. Annual crane inspections are required by regulations.

An effective preventive maintenance program consists of preventive maintenance inspections, compliance inspections where applicable, and routine maintenance. The objective is to help you comply with regulations, follow manufacturer’s recommendations for maintenance, and to reduce the likelihood of failures that result in unplanned downtime.

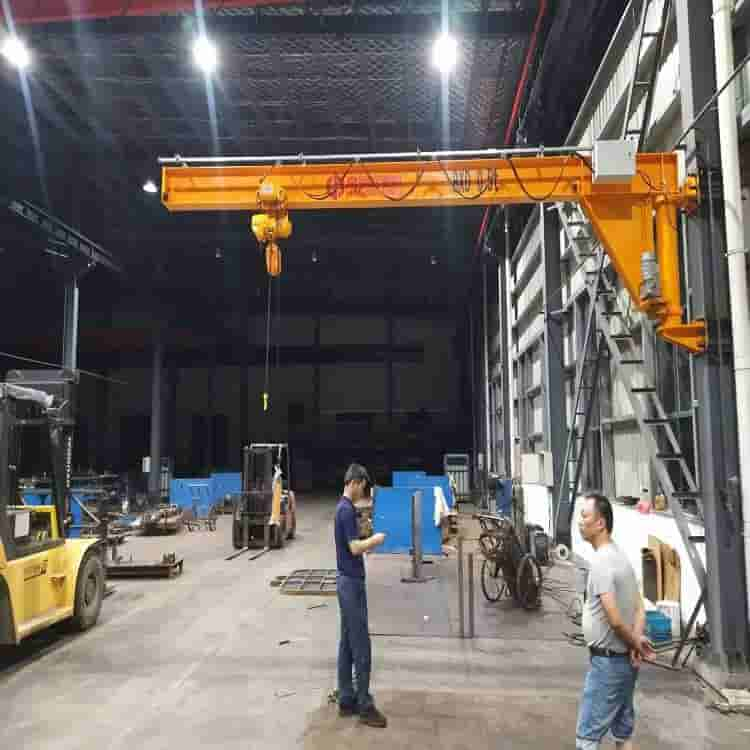

DQCRANES provides the optimal crane services by our experienced and certified engineers for your crane lifetime. The crane maintenance service includes but not limited to the following items:

Corrective crane maintenance for crane means the maintenance to bring your crane back to work or to take measures to restore the crane into a perform condition with desirable functions after a fault or breakdown happened.

Address safety and productivity issues and capitalize on improvement opportunities by making timely repairs, replacing components and/or adding new technology to your crane.

Corrective Maintenance is carried out after a fault is detected and is aimed at restoring your crane to a condition in which it can perform its intended function. Timely repair of known faults reduces the likelihood of emergency breakdowns and is often mandated by regulation.

Retrofits are an efficient option to replace components or add current technology to your existing overhead crane. Common retrofits include replacement of hoists, components, electrics and/or controls, addition of new features, and/or technology upgrades and up-dates. Retrofits typically require minimal downtime, engineering and pre-planning.

Crane modernization is the most cost-effective way to get the current features and technologies to be applied to your aging cranes. crane modernization is conducted according to your requirements.

Modernizations are tailored upgrades or modifications designed to extend the service life of your overhead crane and meet current regulatory, maintenance and production requirements.

Typical modernizations include upgrading open winch trolleys, electrical and automation systems or modifying structures such as girders, lifting beams and runways. Smart Features such as Sway Control, Target Positioning and Protected Areas can deliver further improvements in safety and productivity.

If one or more of these issues apply in your operations, you may want to consider a modernization.

General Use Overhead Crane Maintenance&Operation Manual

Contact our crane specialists

Send us a message and we will get back to you as soon as possible.