The global customization of rubber-tyred gantry cranes is a complex and multi-dimensional challenge, which covers the diversity of operating environments, differences in technical standards, individual customer needs, diversity of laws and regulations, and the balance between technological innovation and sustainable development. These issues not only test the technical strength and market insight of manufacturers, but also reflect their ability and wisdom to cope with complex and changing market environments in the context of globalization.

The operating environments of rubber-tyred gantry cranes are extremely diverse, from busy ports and logistics centers to vast industrial sites, and each environment has unique requirements for its design, manufacturing and installation. In the port environment, the gantry crane needs to face harsh conditions such as sea breeze corrosion and salt spray erosion, which requires manufacturers to consider anti-corrosion performance when designing and use corrosion-resistant materials to ensure that the equipment can operate stably in harsh environments. At the same time, port operations are often accompanied by high-intensity cargo loading and unloading, so the gantry crane must have excellent lifting capacity and stability. In industrial sites, the terrain may be more complex, such as slopes and uneven ground, which requires the gantry crane to have good adaptability and flexibility when designing to ensure safe operation on various terrains. In addition, the climatic conditions in different regions will also affect the performance of the gantry crane, such as high temperature, low temperature, humidity and other environmental factors that need to be taken into account.

The technical standards of countries and regions around the world vary, which requires rubber-tyred gantry crane manufacturers to have a deep understanding of and comply with local specifications and standards. In terms of crane design, manufacturing, installation and inspection, all countries have strict regulations and standards, and manufacturers must ensure that their products meet these standards in order to obtain corresponding certifications and licenses. In addition, different countries and regions have different requirements for crane safety performance, energy efficiency indicators, environmental performance, etc., which requires manufacturers to fully consider these factors in the design and manufacturing process to ensure product compliance and safety.

With the development of the global economy and the intensification of market competition, customers’ demand for rubber-tyred gantry cranes is becoming increasingly personalized. Whether it is lifting capacity, operating range, intelligence level or appearance design, customers hope to be able to customize according to their actual needs. This requires manufacturers to have strong technical strength and innovation capabilities, and be able to provide personalized solutions according to the specific requirements of customers. At the same time, manufacturers also need to fully communicate and exchange with customers to ensure that the design plan can meet customer expectations and needs.

Regulations and policies around the world are constantly being updated and improved, and higher requirements are put forward for rubber-tyred gantry cranes in terms of environmental performance, energy efficiency indicators, safety performance, etc. Manufacturers must pay close attention to changes in regulations and policies in various countries and regions to ensure that products meet local requirements. For example, some countries and regions have strict regulations on crane emission standards, noise control, energy consumption indicators, etc. Manufacturers must ensure that their products meet these requirements to avoid penalties or market access due to violations.

While pursuing technological innovation, manufacturers also need to consider the sustainability of their products. This includes aspects such as material selection, energy consumption, and the maintainability and upgradeability of equipment. Manufacturers need to adopt advanced materials and processes to reduce the energy consumption and emissions of equipment and improve the energy efficiency and environmental performance of equipment. At the same time, manufacturers also need to pay attention to the maintainability and upgradeability of equipment so that they can perform maintenance and upgrades in a timely manner during the use of the equipment, extend the service life of the equipment, and reduce operating costs.

As an important lifting equipment in modern ports, logistics centers and large industrial sites, the customized solutions of rubber-tyred gantry cranes play a vital role in the modern logistics system. These customized solutions not only meet the needs of different operating environments, but also improve operating efficiency and ensure the safety of operation. In the implementation of customized solutions, Dongqi Crane will provide a full range of services, including equipment design, manufacturing, installation, commissioning and after-sales service. These services ensure that the equipment can be put into operation smoothly and receive timely and effective maintenance and support during use.

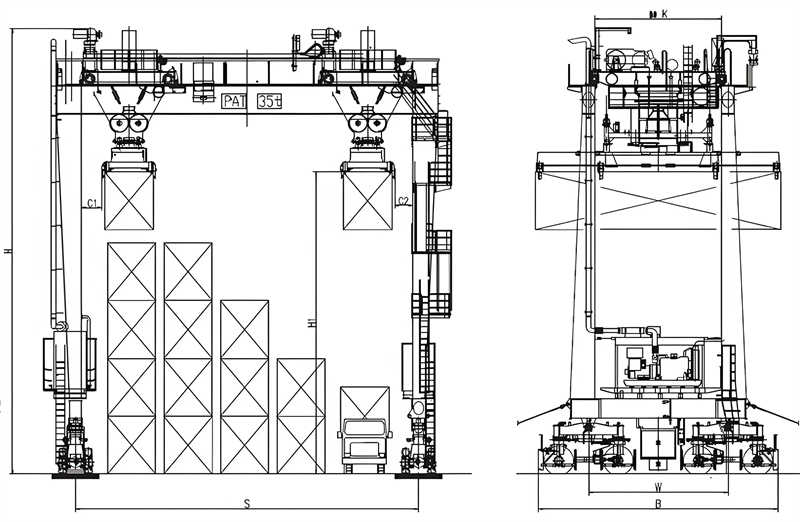

The customized solutions of rubber-tyred gantry cranes meet the needs of different operating environments, improve operating efficiency and ensure the safety of operation with their powerful functional characteristics, intelligent systems, flexible structure and material selection, and load-bearing capacity improvement strategies. The application of these customized solutions not only improves the overall efficiency of the logistics system, but also provides strong support for the development of modern industry. The following are some key customized solutions:

Improved load-bearing capacity:

Mobility and flexibility:

Adaptability to special environments:

For special climates and geographical environments, such as high temperature, low temperature, windy, rainy, etc., special protective devices and control systems can be customized to ensure the stability and safety of the gantry crane.

Constant power speed regulation:

The fully linearized constant power speed regulation technology is adopted to achieve speed increase under light load and improve operating efficiency.

Automatic box search and positioning:

Equipped with advanced automatic box search and positioning system, it automatically runs to the specified position according to the coordinates of the given container to improve operating accuracy and efficiency.

Anti-hook slip and anti-sway control:

Intelligent management:

Hybrid power:

Power supply mode selection:

Pre-sales consultation and solution design:

Manufacturing and quality control:

After-sales service and maintenance:

Customized rubber-tyred gantry cranes may face a wide range of customer types, and customer needs are also different. The following is a detailed analysis of these customer types and needs by Dongqi Crane:

Port and Terminal Operators

This type of customer usually needs to handle a large amount of containerized cargo, and has high requirements for the lifting capacity, operating efficiency, automation level and wind resistance of rubber-tyred gantry cranes.

Logistics and warehousing companies

Logistics and warehousing companies need rubber-tyred gantry cranes to handle a variety of cargo, including containers, bulk cargo, etc. They may pay more attention to the flexibility, mobility and ease of operation of the equipment to quickly transfer and operate between different warehouses and cargo yards.

Steel and Metallurgical Enterprises

Steel and Metallurgical Enterprises usually need to handle heavy steel and metal materials, and have high requirements for the load-bearing capacity, stability and durability of rubber-tyred gantry cranes. They may also need the equipment to have special hoists and clamps to accommodate cargo of different shapes and sizes.

Shipyards and heavy machinery manufacturers

These customers usually need to handle large ship parts and heavy machinery and equipment, and have strict requirements on the lifting capacity, operating range and accuracy of rubber-tyred gantry cranes. They may also require the equipment to have functions such as remote control and intelligent driving to improve the safety and efficiency of operations.

Construction and engineering project contractors

Construction and engineering project contractors need rubber-tyred gantry cranes to handle construction materials and equipment, such as prefabricated components, steel bars, etc. They may pay more attention to the mobility, adaptability and flexibility of the equipment so that it can be quickly deployed and operated in different construction sites and working environments.

Lifting capacity and operating range

Customers usually require rubber-tyred gantry cranes to have sufficient lifting capacity and operating range to meet the handling needs of different goods.

Automation and intelligence level

With the development of technology, customers pay more and more attention to the automation and intelligence level of rubber-tyred gantry cranes. They may require the equipment to have functions such as automatic box search, automatic positioning, and automatic anti-sway to improve operating efficiency and accuracy.

Stability and safety

Customers have strict requirements on the stability and safety of rubber-tyred gantry cranes. They may require the equipment to have safety measures such as windproof devices, anti-skid devices, overload protection devices, etc. to ensure safety and stability during operation.

Flexibility and mobility

Customers usually expect the rubber-tyred gantry crane to have high flexibility and mobility so that they can quickly transfer and operate in different working environments and sites. This includes aspects such as the equipment’s steering ability, driving speed, and tire adaptability.

Durability and maintainability

Customers also have certain requirements for the durability and maintainability of rubber-tyred gantry cranes. They may expect the equipment to have high durability and wear resistance to reduce repair and replacement costs. At the same time, they may also require the equipment to be easy to maintain and maintain so that it can maintain good performance during long-term use.

Customized services

According to the special needs of different customers, they may require customized services, such as the design of special hoists and fixtures, and adaptability modifications to special working environments.

Customized rubber-tyred gantry cranes need to meet different customer types and needs, including port and terminal operators, logistics and warehousing companies, steel and metallurgical companies, shipyards and heavy machinery manufacturers, and construction and engineering project contractors. These customers have different requirements for the equipment’s lifting capacity, operating range, automation and intelligence level, stability and safety, flexibility and mobility, durability and maintainability, and customized services. Therefore, when designing and producing customized rubber-tyred gantry cranes, it is necessary to fully consider the customer’s actual needs and usage scenarios to ensure that the equipment can meet the customer’s expectations and requirements.

Contact our crane specialists

Send us a message and we will get back to you as soon as possible.