Cranes often play an unexpected role in equipment maintenance. The case we are going to analyze today is an injection molding factory. They need to improve the work efficiency of the injection mold repair workshop. For this reason, they approached us to design a new crane system for their workshop.

Before we designed and installed a suspension crane for the shop, they had one jib crane serving three workstations. Since the working weight of metal molds ranges from 50 to 1500 kg, some precautions need to be taken, so toolmakers often have to interrupt work while waiting for the jib crane to be used. After understanding the workflow of the workshop, we decided to give each station its own suspension crane, equipped with two cranes with a lifting capacity of 1.6 tons. Three cranes operate on the same metal structure. In order to avoid accidental collisions, limit switches ensure driving safety.

Below we will focus on analyzing the design process of the suspended bridge crane in this case and our work experience.

The molding shop is the core production activity of an injection molding factory. Mold change operations on 22 Engel, Fanuc or Ferromatik injection molding machines are carried out by overhead cranes equipped with 3-ton hoists. These presses are used for the forming of small pneumatic hose connectors and fittings for compressed air systems in industrial buildings.

The Production Manager of Injection Molding Equipment explains: “We carry out between 300 and 350 part series changes per month, involving as many injection mold replacements. To ensure that the molding shop operates at full capacity, it is first of all crucial that the molds are in perfect condition and, since the molds Operations can only be carried out by suspension cranes, which must therefore be fully serviceable and reliable.

“Even though our activity is complex, it must be understood that it is mainly based on two basic equipment units: plastic injection molding machines and molds. To ensure that production quantities and quality meet our goals, we must ensure regular inspections and routine maintenance of molds, Because we rely heavily on them to ensure the productivity and manufacturing quality of our products.”

The 500 square meter workshop dedicated to daily mold maintenance consists of three continuous square 10m x 10m workstations. After a certain number of work cycles, the mold is removed and ultrasonic cleaned, sometimes requiring the toolmaker to repair the spindle through galvanic corrosion or replace potentially faulty parts.

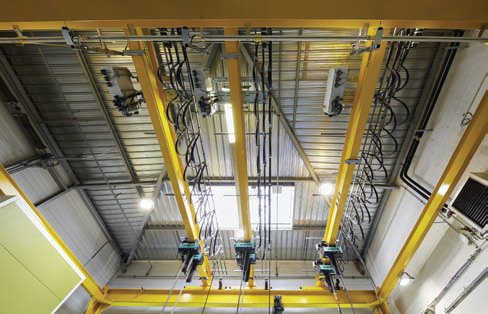

Before the suspension crane was installed, one jib crane served three workstations. Since the operating weight of metal molds, which range from 50 to 1500 kg, requires a number of precautions, toolmakers often have to interrupt work while waiting for the jib crane to be used. Therefore, it was decided to have each station have its own suspended crane equipped with two hoists with a lifting capacity of 1.6 tons. The three cranes travel on the same metal structure. In order to avoid accidental collisions, limit switches ensure driving safety.

The productivity of the daily mold maintenance workshop increased by 25%. Since the mold consists of two parts of different sizes and weights, each crane is equipped with two hoists to facilitate completely safe operation. The hoist chosen has a 2-speed motor for lifting and a variable speed motor for horizontal travel, so the load can be controlled both horizontally and vertically without any swaying effect. The daisy chain power supply is traditional and the control box is wired. For security reasons, this solution was preferred over a wireless system to avoid possible confusion between the control boxes of the three workstations.

Customized cranes have always been the only way to improve work efficiency in various factory workshops. The prerequisite for determining whether a customized crane can work is to clearly understand the customer’s actual needs and working conditions.

In this case, we can clearly see that the customized crane can design the best material handling path according to the specific layout and production needs of the injection molding factory. By reducing the distance and time of material handling, ineffective labor in the production process can be reduced, thereby improving production efficiency. This will test an engineer’s work ability and design experience.

We have been providing customers with customized cranes for a long time, and we have a complete set of crane solutions. If you need to purchase a crane for complex working conditions, you can have a meaningful communication with us.

Contact our crane specialists

Send us a message and we will get back to you as soon as possible.