5 tonelada Grúa de arriba de la Solución(de una Sola Viga)

5 toneladas de propósito General de una Sola Viga de Grúa de arriba

The 5-ton universal single-girder overhead crane is a widely used lifting equipment in industrial settings. It is characterized by its robust design and versatility, making it suitable for a variety of heavy-lifting tasks.

Structurally, the crane features a main girder, typically made of I-beam or box-beam construction, which provides sufficient bearing capacity and stability. Connected to the main girder are end beams that support and stabilize the crane, ensuring smooth movement along the tracks. The crane's movement is facilitated by travel mechanisms, including a main car travel mechanism for lateral movement along the main girder and a trolley travel mechanism for longitudinal movement along the main girder.

The lifting mechanism, consisting of a motor, brake, reducer, drum assembly, and hook pulley block, is driven by an electric motor to achieve lifting and lowering motions. This mechanism is capable of lifting and moving heavy loads weighing up to 5 tons, making it ideal for various industrial applications.

In terms of performance parameters, the crane offers a range of spans, typically between 10 and 30 meters, and lifting heights of 6, 9, or 12 meters, depending on specific requirements. The operating speeds of the main car and trolley can also be adjusted to suit different working conditions, with the main car usually traveling at speeds around 20 meters per minute.

The 5-ton universal single-girder overhead crane finds application in various industries, including machine shops, assembly plants, warehouses, and logistics centers. In machine shops, it is used to lift and move heavy machinery components, enhancing production efficiency. In assembly plants, it aids in lifting and positioning various parts to ensure precise assembly. In warehouses and logistics centers, it facilitates the lifting and stacking of heavy goods, improving storage efficiency and the speed of cargo sorting and transportation.

Safety is a top priority in the design of the crane. It is equipped with limit switches to restrict the movement of the crane and trolley within a predefined working area. Emergency stop buttons are also provided to allow operators to immediately halt all movements of the crane in emergency situations. Additionally, an overload protection device automatically cuts off the power when the crane lifts a weight exceeding its rated capacity, ensuring safe operation.

5 toneladas a la Baja Altura de una Sola Viga de Grúa de arriba

The 5-ton low-clearance single-girder overhead crane is a lifting equipment specially designed for limited height spaces. It has remarkable features and powerful functions. This crane adopts a low structural design, which greatly reduces the height of the space occupied by the crane itself, allowing it to operate flexibly in factories or warehouses with limited heights without being affected by space constraints.

Structurally, it adopts a single beam form, which not only makes the overall structure of the crane simpler, but also reduces its own weight and reduces manufacturing costs. Despite its simple structure, it can still meet basic lifting needs and provide strong support for the hoisting of various heavy materials and equipment.

In terms of working principle, this crane is not much different from an ordinary single-girder overhead crane. It mainly relies on the electric motor to drive the hoisting mechanism, the cart operating mechanism and the trolley operating mechanism to complete the lifting operation. The hoisting mechanism is used to lift and lower heavy objects, the trolley operating mechanism is responsible for the lateral movement of the crane on the main beam, and the trolley operating mechanism realizes the longitudinal movement of the lifting trolley on the main beam.

In terms of performance, this crane has a rated lifting capacity of 5 tons and can handle various heavy-duty lifting tasks. At the same time, its span can be selected according to actual needs to adapt to the width of different factories or warehouses. Although the lifting height is relatively low, it can fully meet the lifting needs in most low spaces. In addition, the running speed of the cart and trolley can also be adjusted according to work needs to further improve work efficiency.

In terms of application, 5-ton low-headroom single-girder overhead cranes are widely used in low-rise factories, warehouses, logistics centers and other fields. In low-rise factories, it can operate flexibly to meet various lifting needs; in warehouses, it can be used to hoist and stack heavy goods to improve warehousing efficiency; in logistics centers, it can speed up the sorting and sorting of goods. Transportation speed improves overall logistics efficiency.

In terms of safety, this crane also performs well. It is equipped with a limiting device to limit the movement range of the cart and trolley to prevent them from exceeding the set working area. At the same time, an emergency stop button is also set up so that all movements of the crane can be stopped immediately in an emergency. In addition, the overload protection device is also an important part of its safety performance. When the weight lifted by the crane exceeds its rated lifting capacity, the device will automatically cut off the power supply to ensure the safe operation of the crane.

5 tonelada Estándar de Europa Eléctrico de la Grúa puente Grúa

HD electric hoist overhead crane is a lifting equipment that combines efficiency, flexibility and durability. It adopts European standard design and has become a model of the new generation of general cranes. This crane not only follows the advanced European industrial manufacturing concept, but also reaches the international leading level in detail processing and overall performance.

Its modular design is a highlight of HD electric hoist overhead crane. By decomposing the crane into multiple independent modules, it not only makes the installation process easier and faster, but also greatly improves the maintainability and scalability of the equipment. When a module fails, the operator only needs to replace or repair the module without disassembling the entire crane, thereby reducing maintenance costs and downtime.

In addition, HD electric hoist overhead crane also adopts a maintenance-free design concept. For key components such as electric hoists, reducers, brakes, etc., high-quality materials and advanced manufacturing processes are selected to ensure the stability and reliability of the equipment in long-term operation. At the same time, these components have also undergone rigorous testing and inspection to ensure that they can meet the needs of various harsh working environments.

In terms of lifting capacity, HD electric hoist overhead crane also performs well. Its electric hoist adopts advanced European technology and manufacturing process, with strong lifting capacity and precise control performance. Whether it is lifting heavy materials or performing precise assembly operations, this crane can provide stable and efficient lifting services.

In terms of safety, the HD electric hoist overhead crane is also trustworthy. It is equipped with a variety of safety protection devices, such as limiters, overload limiters, sound and light alarm devices, etc., to ensure safety and stability during the lifting process. At the same time, its electrical control system also adopts advanced technology and design concepts, allowing operators to control the various functions of the crane more conveniently and accurately.

5 tonelada a prueba de Explosión de una Sola Viga de Grúa de arriba

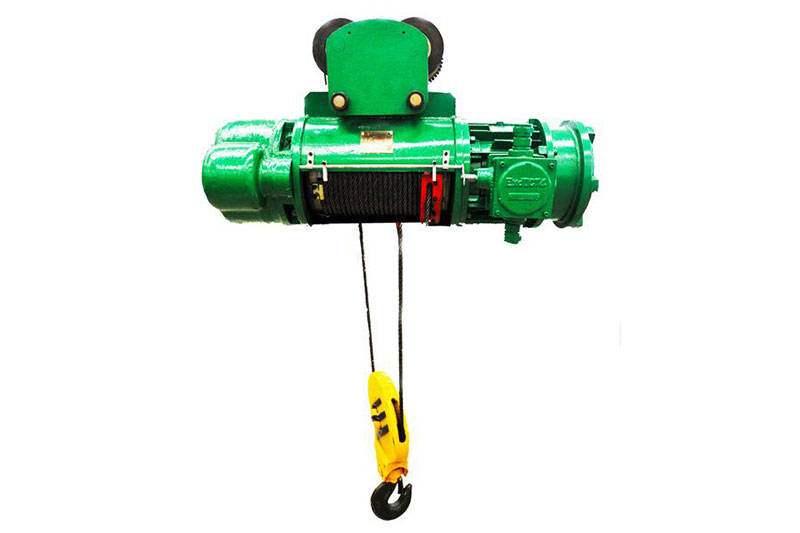

The 5-ton explosion-proof single-beam overhead crane is a lifting equipment specially designed for explosive environments. It combines explosion-proof performance, compact structure, efficient lifting, safety and stability. This crane adopts special explosion-proof technology to ensure safe operation in industrial environments containing explosive gases or steam. All electrical components and wiring are explosion-proof, effectively avoiding the risk of explosion caused by electric sparks or arcs.

The design of its single-beam structure not only makes the overall structure of the crane compact, light, easy to install and maintain, but also enhances the stability of operation and reduces vibration and noise. At the same time, the 5-ton rated lifting capacity allows it to meet the lifting needs of various heavy materials. Advanced lifting technology and optimized structural design ensure stability and safety during the lifting process.

In industrial fields such as chemical, petroleum, and coal mines where explosive gases exist, 5-ton explosion-proof single-beam overhead cranes have been widely used. It can not only effectively avoid safety accidents that may be caused by traditional lifting equipment in explosive environments, but also improve the efficiency of material lifting and transportation. In addition, the crane is also equipped with a variety of safety protection devices, such as limiters, overload limiters, etc., which further improve the safety of lifting operations.

5 tonelada Grúa de arriba de la Solución (de la Viga Doble)

5 toneladas de la Viga Doble Sobrecarga de la Grúa Puente (de tamaño mediano)

Más comúnmente utilizado un pequeño equipo de manipulación de material adecuado para la mayoría de las fábricas, almacenes, etc.

The LH 5-ton double-beam overhead crane is an efficient and versatile lifting equipment. From the basic structure, the crane adopts a double-beam structure, which enables the crane to bear a larger load and ensure the safe operation of the equipment during operation. Its bridge-type main beam, as a load-bearing structure connecting the two ends, plays the role of supporting and transferring the load, while the secondary beam is set above the main beam to carry the electric hoist and cargo load. In addition, the crane is also equipped with a rotatable hook and ring to facilitate the movement of goods in the space and improve the operation efficiency.

In terms of performance parameters, the LH 5-ton double-beam overhead crane has a rated lifting capacity of 5 tons, a wide range of applicable spans, usually between 7.5 meters and 35 meters, and an effective lifting height of 6 meters to 30 meters. The trolley running speed is generally between 20 meters/minute and 70 meters/minute, which can meet the needs of different operation scenarios. At the same time, the working level of the crane is A3 to A5, and the working environment temperature range is between -25℃ and 40℃, which has a wide range of applicability.

In terms of operation mode, the LH 5-ton double-girder overhead crane provides a variety of options such as ground operation, cab operation and remote control operation. The cab is available in open and closed types, and can be installed on the left or right side according to actual conditions. There are also three options for entry direction: side, end and top, to meet the needs of users. This flexible operation mode enables the crane to be suitable for various complex working environments, improving operating efficiency and safety.

In addition, the LH 5-ton double-girder overhead crane also has the advantages of compact appearance, low building clearance height, light weight and small wheel pressure. These advantages make the crane more convenient during installation, use, maintenance and transportation, and reduce the user's operating costs. At the same time, the crane also complies with the GB/T3695-1994 "Electric Hoist Overhead Crane" standard, ensuring the quality and performance of the product.

In terms of application, the LH 5-ton double-girder overhead crane is widely used in mechanical processing workshops, auxiliary workshops of metallurgical plants, warehouses, material yards, power stations and other fields for the transfer, assembly, maintenance and loading and unloading of goods. In addition, it can also replace ordinary double-beam overhead cranes and be used in production workshops in the light textile industry and food industry.

5 tonelada Grúa de arriba de la Viga Doble (de Gran tamaño)

The QD 5-ton double-girder overhead crane is a heavy-duty lifting equipment designed to meet the lifting needs of various industrial fields. Its structure mainly consists of two sturdy main beams, end beams, lifting trolleys, electronic control systems and cabs, which together build a stable and efficient lifting system.

The rated lifting capacity of the crane is 5 tons, which can easily handle a variety of heavy object handling tasks. Its span can be customized according to specific application scenarios and user needs to adapt to different sizes of working areas. At the same time, the lifting height is also carefully designed to ensure that it can meet the lifting needs of different heights.

In terms of operation and control, the QD 5-ton double-girder overhead crane provides flexible and diverse options. The driver's cab can be either closed or open, and even an insulated driver's cab can be provided according to special requirements, and air conditioners or air coolers are installed inside to ensure the comfort and work efficiency of the operator. In addition, the crane also supports ground control or wireless remote control control systems, making operation easier, more flexible and safer.

The crane has a sturdy structure and strong load-bearing capacity, and can cope with various complex and harsh industrial environments. It has a wide range of applications and is suitable for many fields and departments such as manufacturing and assembly line workshops, chemical plants, and freight yards. Whether it is moving large workpieces, assembling parts, or loading and unloading chemical raw materials and finished products, the QD 5-ton double-beam overhead crane can provide reliable support.

In order to ensure the safety and reliability of lifting operations, the QD 5-ton double-beam overhead crane is also equipped with an overload limiter and an alarm display device. These safety devices can promptly issue an alarm when the crane is overloaded or an abnormal situation occurs, and take necessary protective measures, thereby effectively avoiding accidents.

5 tonelada a prueba de Explosiones de la Grúa de arriba de la Viga Doble

The 5-ton explosion-proof double-girder overhead crane is a lifting equipment designed for operation in explosive environments with flammable gases or steam. This crane not only has all the functions of an ordinary double-girder overhead crane, but also adopts a special explosion-proof design to ensure safety when used in hazardous environments.

Its main structure consists of two high-strength main beams and end beams to form a stable lifting platform. The main beams and end beams are made of high-quality steel, with extremely high load-bearing capacity and fatigue resistance, and can adapt to the needs of frequent use and high-intensity work. At the same time, the trolley mechanism and the trolley mechanism of the crane are responsible for lateral and longitudinal movement respectively, so that the load can be flexibly moved in the working area.

In terms of explosion-proof design, the 5-ton explosion-proof double-girder overhead crane adopts a variety of advanced technologies. For example, the motor adopts a flameproof design, which can prevent it from igniting flammable gases when electric sparks or arcs are generated. In addition, the crane's transmission system, control system and electrical components also meet explosion-proof standards and can operate safely in explosive environments.

The crane has a lifting capacity of 5 tons and is suitable for handling and loading and unloading operations of various heavy goods. It runs stably, is easy to operate, and is equipped with complete safety protection devices, such as overload limiters and limit switches, to ensure the safety and reliability of lifting operations.

In terms of application scenarios, 5-ton explosion-proof double-beam overhead cranes are widely used in industrial fields with explosive hazards such as petroleum, chemical industry, and coal mines. In these fields, cranes can not only improve production efficiency and reduce labor intensity, but also ensure the safety and reliability of the operation process.

Tabla de comparación de 5 ton de Sobrecarga de la Grúa Puente

| La sobrecarga de la grúa Puente | Capacidad | Span | Altura | Área De Cobertura De Tipo De | Área De Cobertura | Motorización |

| Propósito General de una Sola Viga de Grúa de arriba | 5 ton | 7.5 m 31,5 m | personalizar | Cuadrado/Rectángulo | 31.5 m x Longitud Ilimitada | Sí |

| La Baja Altura De Una Sola Viga De Grúa De Arriba | 5 ton | 7.5 m 31,5 m | personalizar | Cuadrado/Rectángulo | 31.5 m x Longitud Ilimitada | Sí |

| De una sola Viga de Grúa de arriba - estilo Europeo | 5 ton | 7.5 m 31,5 m | personalizar | Cuadrado/Rectángulo | 31.5 m x Longitud Ilimitada | Sí |

| Se montan en el techo de la Estación de trabajo de la Grúa Puente | 5 ton | 7.5 m 31,5 m | personalizar | Cuadrado/Rectángulo | 31.5 m x Longitud Ilimitada | Sí |

| A prueba de explosión de una Sola Viga de Grúa de arriba | 5 ton | 7.5 m 31,5 m | personalizar | Cuadrado/Rectángulo | 31.5 m x Longitud Ilimitada | Sí |

| De la Viga doble Sobrecarga de la Grúa Puente (de tamaño mediano) | 5 ton | 7.5 m 31,5 m | personalizar | Cuadrado/Rectángulo | 31.5 m x Longitud Ilimitada | Sí |

| Grúa de arriba de la Viga doble (de Gran tamaño) | 5 ton | 7.5 m 31,5 m | personalizar | Cuadrado/Rectángulo | 31.5 m x Longitud Ilimitada | Sí |

| A prueba de explosiones de la Grúa de arriba de la Viga Doble | 5 ton | 7.5 m 31,5 m | personalizar | Cuadrado/Rectángulo | 31.5 m x Longitud Ilimitada | Sí |