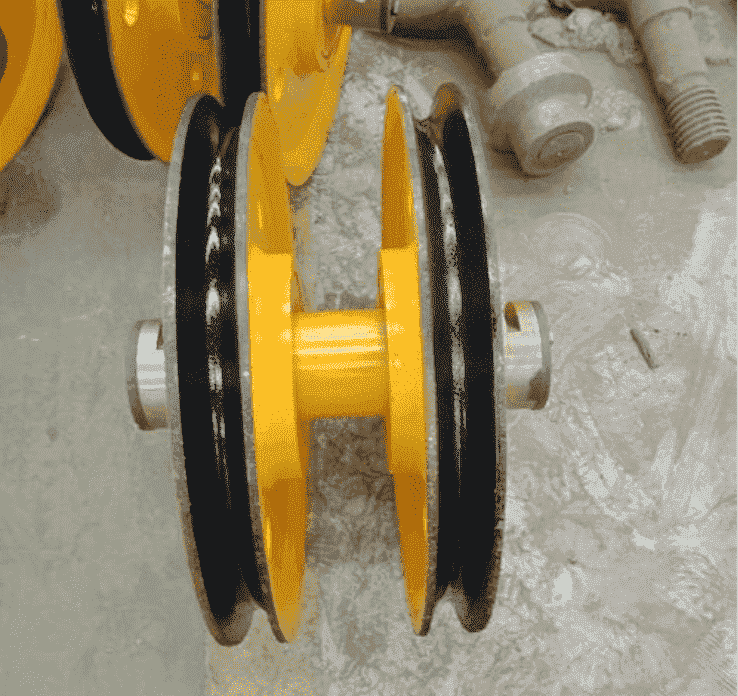

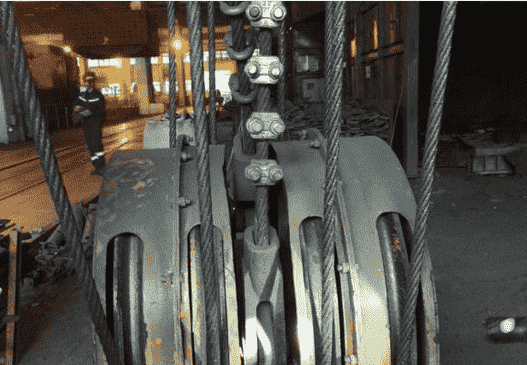

When the crane is working, the crane pulley working system plays a very important role. The winding steel wire rope rotates to transmit the tension, and the direction of the tension can be changed, and the purpose of labor saving can be achieved. If the pulley of the crane fails, the steel wire rope will fall off the groove or slide, which will cause serious consequences. Therefore, the failure analysis of crane pulley is of great significance in safety and economy.

During the working process of the crane, the pulley working system of the crane bears the tensile force from the steel wire rope. After working for a period of time, fatigue wear will occur. Fatigue wear is contact fatigue. When the two contact bodies slide or roll relatively, the cyclic stress formed in the contact area exceeds the fatigue strength of the material, cracks appear and expand continuously, resulting in wear. Wear is the main reason for the failure of crane pulley.

After a certain degree of pulley indentation occurs, pulley indentation failure will occur. The main reasons include:

In addition to the bending stress caused by movement on the pulley, the wire rope also bears the radial pressure caused by its contact with the pulley. This pressure will produce shear stress in the wire rope, change the structure of the wire rope and affect the wear rate of the pulley rope groove. Therefore, when selecting an appropriate steel wire rope structure, the magnitude of this pressure and the anti-wear performance of pulley materials should be considered. For example, a hot-rolled pulley with good quality can be selected.

The important reason for the indentation of the wheel groove is the impact load. In the process of lifting and transportation, the contact stress caused by acceleration or lifting is (1 ~ 2) times of the uniform stress, so it is very important to study the wire rope winding system. In the process of practical application, the acceleration should be controlled in time to reduce the impact load borne by the pulley and the friction coefficient between the steel wire rope and the pulley groove.

By analyzing the operation principle of the steel wire rope and pulley during the working process of the crane, it can be concluded that the indentation of the pulley is mainly because the main force bearing point of the pulley block is concentrated at the bottom of the pulley groove. When lifting heavy objects with slings, due to the influence of shaking and other factors, the alternating friction of the steel wire rope will cause fatigue wear to the pulley groove and produce obvious indentation at the bottom of the pulley, Crack propagation and fracture will have serious consequences. Therefore, the pad matched with the diameter of the steel wire rope can be installed according to the surface area to strengthen the contact stress between the steel wire rope and the pulley and reduce the friction between the steel wire rope and the pulley groove.

When the crane works for a long time, it will inevitably wear between the steel wire rope and the pulley groove of the crane. The impurities generated by the wear on the surface of the pulley groove will be integrated into the grease, resulting in the increase of resistance between the steel wire rope and the pulley groove and the aggravation of the wear degree. Therefore, the lubricating grease should be replaced in time to reduce wear consumption.

Contact our crane specialists

Send us a message and we will get back to you as soon as possible.