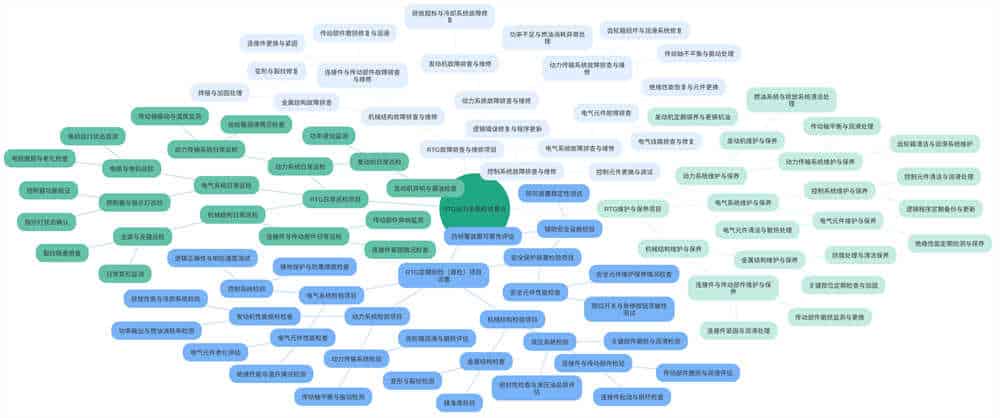

As a key equipment in port logistics, RTG (Rubber-tired container gantry crane), its safety performance and operating status directly affect the efficiency and safety of the entire logistics chain. In order to ensure the stable operation of RTG, regular inspections (including the first inspection) are particularly important. The inspection project not only covers a number of aspects such as mechanical structure, electrical system, and power system, but also strictly follows a series of clear requirements. Starting from the classification of RTG in the special device directory, combined with the relevant provisions of the State Administration of Quality Supervision, Inspection and Quarantine, we can deeply understand the uniqueness and necessity of RTG regular inspection. In addition, the comparison with the general door crane will also help us to clearly grasp the special requirements of the RTG test. This article aims to comprehensively explore the project settings and requirements of regular inspection of RTG, and provide a strong guarantee for the safe and efficient operation of port logistics.

RTG (Rubber-Tired Gantry Crane, rubber tire crane) is a heavy lifting device that is clearly classified in the category of special equipment. According to relevant national laws and regulations, special equipment refers to equipment that is widely used in production and life, and once a fault or accident may pose a major threat to the safety of people’s lives and property. Such equipment requires strict safety supervision and regular inspection. RTG happens to meet this requirement. Because of its unique structure and work characteristics, it occupies an important position in the special equipment directory, and its inspection standards and processes are more stricter and meticulous.

The State Administration of Quality Supervision, Inspection and Quarantine (the General Administration of Quality Supervision, Inspection and Quarantine) has formulated a series of detailed inspection standards and regulations for special equipment such as RTG. These regulations are designed to ensure that special equipment such as RTG can maintain a good operating state in the process of long -term use and avoid safety accidents. These regulations cover the structure, performance, and safety protection devices of the equipment. For example, key components such as RTG’s tire walking mechanism, container hanging device, and electrical control system have clear inspection standards and requirements.

Overview of RTG equipment inspection regulations

| Inspection project | Inspection content | Inspection standards | Note |

| Equipment classification | RTG’s location in the Special Equipment Catalog | Special equipment | Requires strict safety supervision and regular inspection |

| Structural inspection | The overall structure stability of the equipment | _ | Ensure that the structure is free of deformation and cracks |

| Tire Traveling Mechanism | Tire wear, walking trajectory, etc. | Clear inspection standards and requirements | Pay attention to the wear of the tire and make sure that walking is stable |

| Container lifting device | Lifting capacity, reliability, etc. | Clear inspection standards and requirements | Ensure that the lifting device is not damaged and the lifting process is safe |

| Electrical control system | Control accuracy, safety, etc. | Clear inspection standards and requirements | Check that the control system is running normally and there are no safety risks |

| Safety protection device | Effectiveness of various safety devices | _ | Ensure that various safety devices operate normally and play a protective role |

| Difference from general purpose gantry cranes | Targeted inspection items | Formulated based on RTG characteristics | Such as the wear and tear of the tire travel mechanism, the reliability of the container lifting device, etc. |

RTG equipment inspection related agencies and regulations

| Organization name | Responsibilities | Relevant regulations/standards | Note |

| PRC State Administration of Quality Supervision and Quarantine | Establishment of inspection standards and regulations for RTGs and other special equipment | Cover the equipment structure, performance, safety protection device and other aspects | Responsible for the safety supervision of special devices such as RTG |

| Special equipment inspection agency | Perform periodic inspections of RTG equipment | According to the inspection standards and regulations formulated by the State Administration of Quality Supervision, Inspection and Quarantine (AQSIQ) | Ensure that RTG equipment runs safely for a long time |

| RTG equipment manufacturer | Provide technical support and information required for equipment inspection | Follow the relevant national standards and regulations | Assist inspection agencies to complete equipment inspections |

| Utilization unit | Responsible for the daily maintenance and repair of equipment, with the inspection agency to carry out inspections | Follow the relevant national standards and regulations to ensure the normal operation of the equipment | _ |

RTG and general gantry cranes have certain similarities in structure and function, but RTG has unique advantages in tire travel and container lifting. Therefore, in terms of inspection standards and items, although RTG and general gantry cranes have some reference, they still need to be inspected specifically according to their own characteristics. For example, for general gantry cranes, the inspection focus may be on the stability of the structure, the flexibility of the operating mechanism, etc. For RTG, in addition to these basic requirements, special attention should be paid to special requirements such as the wear of the tire traveling mechanism and the reliability of the container lifting device.

The mechanical structure is the basis for the stable operation of RTG, so a comprehensive and detailed inspection is required in the first inspection. First of all, for the metal structure of RTG, including the main beam, outriggers, door frames and other key parts, it is necessary to check whether there are problems such as deformation or cracks. Deformation may affect the running track and stability of RTG, while cracks may cause the structural strength to decrease and affect the overall safety. Therefore, professional testing equipment and methods are needed to conduct a comprehensive and accurate inspection of these parts.

Connectors and transmission components are important components of the mechanical structure of RTG. Connectors include bolts, nuts, pins, etc., which need to be checked for looseness or damage. Transmission components include bearings, gears, etc., which need to be checked for wear and lubrication. Wear may cause a decrease in transmission efficiency or even cause failures; while poor lubrication may increase friction and accelerate component wear. Therefore, the inspection of these components is also an important part of the first inspection.

In addition to the above components, the hydraulic system of RTG also needs to be inspected. The hydraulic system is an important power source for RTG, and its stability is crucial to the operation of RTG. It is necessary to check the wear and lubrication of key components such as hydraulic pumps and hydraulic motors, as well as whether the quality and amount of hydraulic oil meet the requirements. At the same time, the sealing of the hydraulic system also needs to be checked to ensure that it will not leak or have other problems.

As the control center of RTG, the stability and reliability of the electrical system are crucial to the normal operation of RTG. In the first inspection, the electrical system needs to be fully inspected and tested.

The insulation performance and temperature rise of electrical components such as cables, motors, and controllers are the key inspection items in the first inspection. The decline in insulation performance may cause electrical failures and affect the normal operation of RTG; while excessive temperature rise may cause electrical components to overheat and cause safety accidents such as fire. Therefore, professional testing equipment is needed to conduct a comprehensive and accurate inspection of these electrical components.

In addition to the above-mentioned electrical components, the logical correctness and response speed of the control system also need to be checked. The logical correctness of the control system is the key to ensure the normal operation of RTG, and strict testing and verification are required. The response speed will affect the operating efficiency of RTG, and relevant tests and adjustments are required. At the same time, the grounding protection and lightning protection measures of the electrical system need to be checked to ensure that they meet the relevant safety regulations and requirements.

The power system provides the power required for the operation of RTG and is the core part of the entire system. For RTGs that use diesel generator sets as power units, the various performance indicators of the engine need to be focused on in the first inspection. First, it is necessary to check whether the power output of the engine is normal and whether it can meet the operating requirements of the RTG. Secondly, it is necessary to check whether the fuel consumption rate of the engine meets the prescribed requirements to avoid waste and pollution. In addition, it is necessary to check whether the emission performance of the engine meets the standards to meet environmental protection requirements. Finally, it is necessary to check whether the cooling system of the engine can work normally to ensure that the engine will not overheat during operation.

In addition to the engine itself, the power transmission system also needs to be checked. The power transmission system includes components such as the drive shaft and the gearbox. The efficiency and stability of these components directly affect the operating effect of the RTG. It is necessary to check whether the drive shaft is well balanced and whether there are problems such as swing or vibration; the gearbox needs to check its lubrication condition and gear wear to ensure that it can transmit power normally. At the same time, the entire power system needs to be debugged and tested as a whole to ensure that it can achieve the best operating state.

Safety protection devices are the last line of defense for the safe operation of RTG, and a comprehensive and detailed inspection is required during the first inspection. First, it is necessary to check whether the sensitivity and reliability of safety components such as limit switches and emergency stop buttons are normal. The function of the limit switch is to limit the operating range of the RTG to avoid accidents such as collisions or overloads; the emergency stop button is to quickly stop the operation of the RTG in an emergency. The sensitivity and reliability of these safety components are directly related to the safety performance of the RTG, so strict testing and verification are required. At the same time, it is also necessary to check the maintenance of these safety components to ensure that they can maintain good performance for a long time. In addition to the above-mentioned safety components, auxiliary safety facilities such as windproof devices and anti-overturning devices also need to be inspected. The function of the windproof device is to prevent the RTG from accidentally moving or overturning under strong winds; the anti-overturning device is to prevent the RTG from overturning during operation. These auxiliary safety facilities are of great significance to improving the safety performance of RTG, so they also need to be comprehensively inspected and tested to ensure that they can play their due role in emergency situations and improve the safety performance of the entire system.

The setting of the regular inspection cycle and frequency of RTG needs to take into account multiple factors, including the frequency of use of the equipment, the working environment, the manufacturer’s recommendations, and the importance of the equipment. Generally speaking, the newly purchased RTG equipment needs to be inspected for the first time before it is put into use to ensure that the quality and performance of the equipment meet the requirements.

After the first inspection, regular inspections need to be carried out according to the established inspection cycle. This inspection cycle can be adjusted appropriately according to the use of the equipment and the manufacturer’s recommendations. For equipment with harsh operating environments or frequent full-load operation, the inspection cycle may be appropriately shortened to ensure the safety and reliability of the equipment.

Before inspection, the RTG needs to be fully cleaned and maintained to ensure that the equipment is in a good state for inspection. Cleaning work includes removing dust, oil and other debris on the surface of the equipment to ensure the accuracy of the inspection results. Maintenance work includes checking whether the various components of the equipment are intact and whether there are any abnormal conditions.

In addition to cleaning and maintenance work, it is also necessary to prepare necessary inspection tools and equipment. These tools and equipment include various measuring instruments, testing instruments, tools, etc. When preparing tools and equipment, it is necessary to ensure the accuracy and reliability of these tools and equipment to avoid errors in the inspection results due to problems with tools and equipment.

Before the inspection, it is also necessary to be familiar with the inspection process and standards. This includes understanding the steps, methods, requirements, etc. of the inspection. Being familiar with the inspection process and standards can help inspectors better carry out the inspection work and improve the efficiency and accuracy of the inspection.

In addition, it is necessary to communicate with the operator to understand the operating status of the equipment. The operator has a more direct understanding of the operating status of the equipment and can provide important information about the operating status of the equipment. Communicating with the operator can help the inspector better identify and solve problems and improve the effectiveness of the inspection.

During the inspection process, it is necessary to strictly abide by the safety operating procedures to ensure the safety of the inspectors. The safety operating procedures include various safety precautions, operating requirements, etc. Compliance with the safety operating procedures can effectively avoid the occurrence of various safety accidents.

For projects that require high-altitude operations or entering the interior of the equipment for inspection, corresponding safety protection measures need to be taken. These measures include the use of safety belts, the setting of safety railings, etc. Taking appropriate safety protection measures can effectively ensure the safety of inspectors.

During the inspection, it is necessary to ensure that the equipment is in a power-off or locked state to avoid personal injury caused by accidental startup. This requires taking appropriate measures to ensure that the power supply of the equipment is cut off or locked. Ensuring that the equipment is in a power-off or locked state can effectively avoid personal injury caused by accidental startup.

After the inspection, the inspection results need to be recorded in detail and the equipment status needs to be evaluated. The content of the record includes the data and results of various tests. The format of the record needs to be standardized, accurate and clear. The evaluation of the equipment status requires a comprehensive evaluation of the performance and condition of the equipment. The results of the evaluation need to be accurate, objective and fair.

For the problems and hidden dangers found, it is necessary to formulate corrective measures in a timely manner and track the rectification. Corrective measures need to be specific, feasible, and effective, and can solve the problems and hidden dangers found. Tracking the rectification can ensure that the problems are solved in a timely manner and avoid the same problems and hidden dangers from recurring.

Submit the inspection results and assessment reports to the relevant departments and personnel for subsequent management and decision-making. This includes summarizing and analyzing the recorded data, results and other information, and providing them to the relevant departments and personnel for reference and management decisions. It can effectively help the relevant departments and personnel understand the condition and performance of the equipment and formulate better management and maintenance plans.

RTG Test Result Record Sheet

| Inspection items | Inspection standard | Test results | Note |

| Equipment Appearance | No visible damage, corrosion | _ | |

| Electrical system | Insulation resistance, grounding resistance in accordance with the standard | _ | |

| Mechanical components | No looseness, wear, deformation | _ | |

| Safety device | Intact and valid | _ | |

| Control system | Stable operation and quick response | _ | |

| Communication system | Clear and accurate signal transmission | _ | |

| Braking system | Good brake effect, no abnormalities | _ | |

| Rails and Traveling Mechanisms | The track is flat and the walking is smooth | _ | |

| Ancillary equipment | In good condition and functioning properly | _ | |

| Comprehensive assessment | Equipment performance, good condition | _ |

Precautions before RTG inspection

| Preparations | Specific content | Responsible person |

| Equipment cleaning | Remove dust, oil and other debris from the surface of the equipment | Maintenance staff |

| Tool preparation | Prepare the necessary inspection tools and equipment and ensure accuracy and reliability | Inspector |

| Familiarize yourself with the process | Familiar with the inspection process and standards, understand the steps, methods and requirements of inspection | Inspector |

| Communicate and understand | Communicate with operators to understand the operating conditions of the equipment | Inspectors and operators |

| Safety protection | Adopt appropriate safety measures, such as the use of safety belts, set up safety rails, etc. | Safety supervisor |

| Device status | Ensure that the device is powered off or locked to avoid accidental startup | Operator |

| Preparation of records | Prepare forms for recording test results and templates for evaluation reports | Inspector |

| Other preparations | Prepare other necessary pre-inspection preparations, as appropriate | Related personnel |

For RTG (Rubber-tired container gantry crane) equipment that uses diesel generator sets as power units, special attention should be paid to the maintenance and care of the engine during the inspection process. This is a key link to ensure the normal operation and safe production of the equipment. During the inspection, the quality of the engine oil needs to be checked first. Engine oil is an important element of the engine lubrication system, which can reduce the wear of internal engine components and ensure smooth operation of the engine. When checking the engine oil, it is necessary to observe the color and viscosity of the engine oil to ensure that the engine oil has not deteriorated or expired. At the same time, the amount of engine oil should also be checked to ensure that the oil level is within the normal range. Secondly, the quality of the engine coolant needs to be checked. The function of the coolant is to reduce the temperature of the engine and prevent the engine from overheating. During the inspection, it is necessary to observe the color and concentration of the coolant to ensure that the coolant has not leaked or failed. In addition, the amount of coolant should be checked to ensure that the coolant level is within the normal range. The cleanliness of the engine filter also needs to be checked. The filter can filter impurities and dust inside the engine to prevent impurities from entering the engine and causing wear. During the inspection, it is necessary to observe the appearance and cleanliness of the filter to ensure that the filter is not damaged or blocked. In addition to the above-mentioned liquid inspection, the output voltage, frequency and power of the generator set must also be measured. These parameters are important indicators of the performance of the generator set and directly affect the normal operation of the equipment. During the inspection, professional tools need to be used for measurement to ensure that these parameters meet the requirements of the equipment operation.

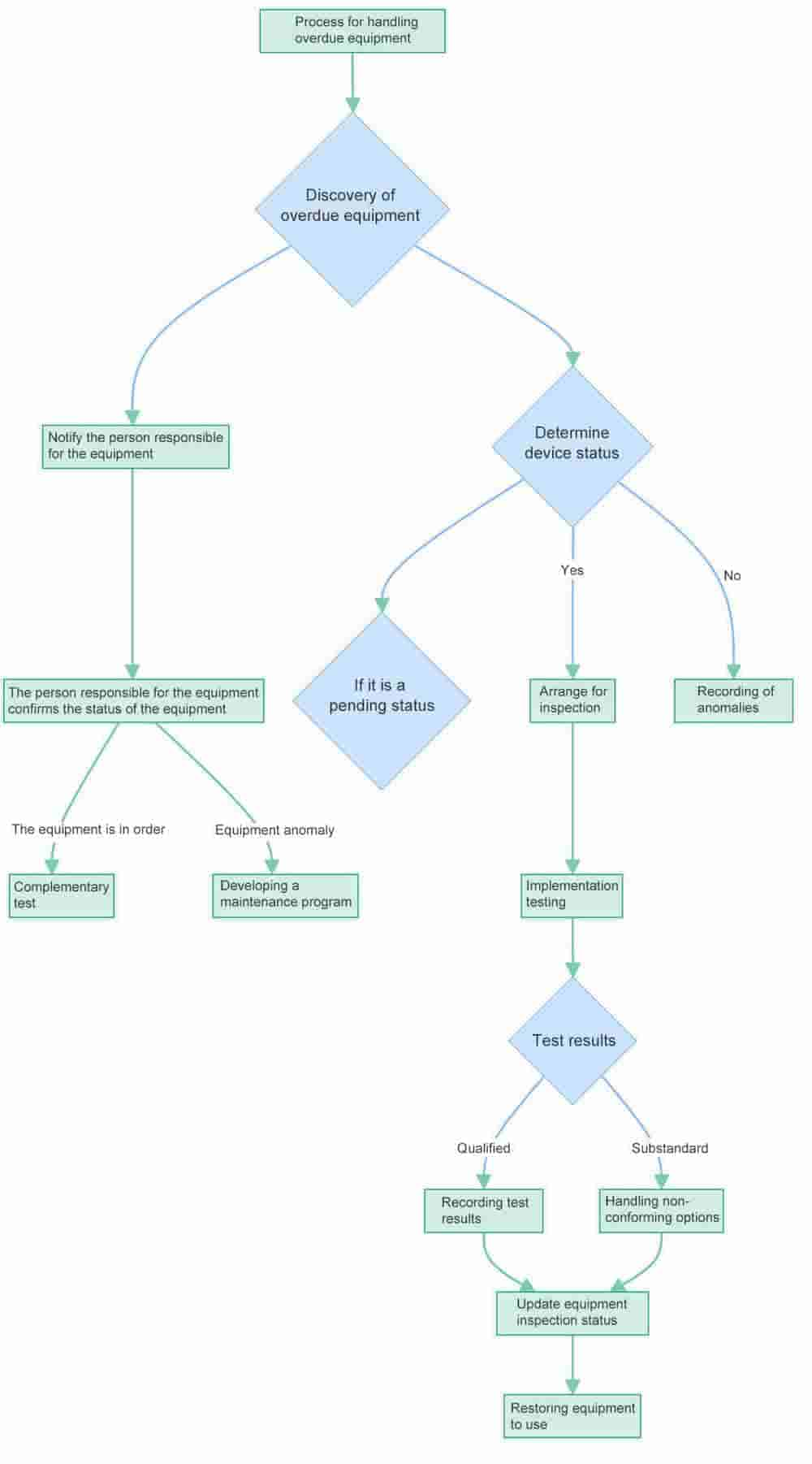

For RTG equipment that has not been inspected on time for some reason, it is necessary to follow a special handling procedure. This process is designed to ensure the safety and compliance of the equipment and avoid safety hazards caused by untimely inspection. First, a comprehensive safety inspection of the equipment is required. This inspection is designed to discover possible safety hazards and problems in the equipment. The content of the safety inspection includes the inspection of key components such as the structure, electrical system, hydraulic system, and brake system of the equipment. Through the safety inspection, it can be assessed whether the equipment has safety hazards. If the equipment has safety hazards, it needs to be stopped immediately and rectified. Corrective measures need to be formulated according to the problems existing in the equipment, including repairs, replacement of parts, adjustment of parameters, etc. After the rectification is completed, the equipment needs to be re-inspected to ensure that the equipment meets safety requirements before it can be put into use. At the same time, it is necessary to report the overdue inspection to the relevant departments. The content of the report includes the name, model, service life, reasons for non-inspection, etc. of the equipment. The purpose of the report is to let the relevant departments understand the actual situation of the equipment for subsequent management and supervision. Before the inspection procedures are completed, the equipment shall not be put into use without authorization. This is to ensure the safety and compliance of the equipment and avoid safety hazards caused by untimely inspection. The inspection procedures need to be carried out in accordance with relevant regulations, including filling in the application form, submitting relevant materials, paying the inspection fee, etc.

In summary, the formulation and implementation of the setting and requirements of the RTG regular inspection (first inspection) project are of great significance to ensure the safe and efficient operation of the equipment. Relevant practitioners should strictly abide by the inspection standards and procedures, continuously improve the inspection level and ability, and contribute to the safe and efficient development of port logistics.

Contact our crane specialists

Send us a message and we will get back to you as soon as possible.