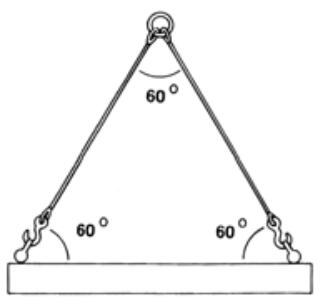

Make sure the horizontal distance between the points of attachment of the load does not exceed the length of the slings. This will ensure the angle between the two legs of the sling does not exceed 60°.

The recommended maximum angle between the two legs of a sling is 90°.

The recommended maximum angle between the vertical and any leg of a sling is 45°.

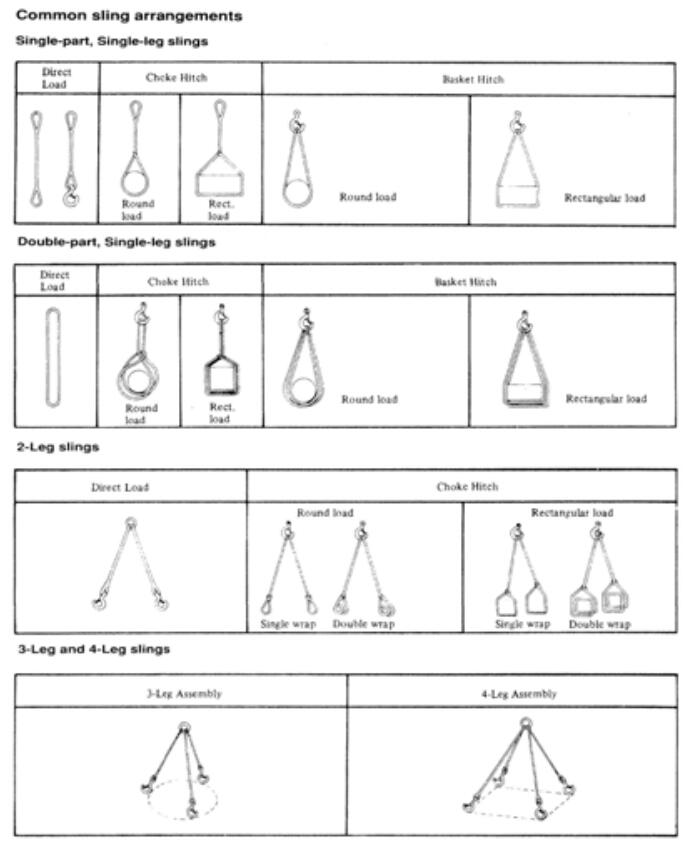

When slinging a rigid object with a multi-legged sling it must be assumed that only two of the sling legs are taking the load. Additional legs do not increase the SWL of the sling assembly.

The maximum angle (a) between legs of slings should not exceed the following:

The SWL of a multi-legged sling assembly is assessed on the diagonally opposite legs.

Where an object is flexible and the load is evenly distributed make sure that each leg takes an even share of the load.

Be careful when lifting irregular shaped objects – it is possible that only one leg of the sling is taking the whole load.

The larger the angle from the vertical made by slings on a hook the more likely the slings eye is to slip off the point of the bill.

In this case, put the eyes into a ‘bow’ shackle large enough so that they do not jam. Make sure that the shackle pin is resting on the hook.

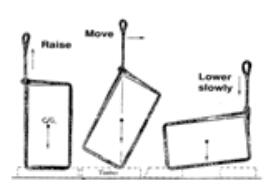

It is the duty of a dogger to direct the crane operator to position the head of the jib or the lifting assembly directly over the load.

Always lift vertically. If the hook is not directly over the load, the load will begin to swing dangerously as soon as it is raised. Dragging a load can put undue strain on the lifting gear and crane boom especially if the load is dragged from the side.

Machinery, plant, personnel boxes, material safety boxes and fuel containers with lifting lugs, must have the SWL clearly marked. All loads delivered to a site that could be hazardous should be strapped or wrapped.

Caution: Many serious accidents occur as strapping, wrapping or loading binding chains are removed.

For example:

Spreaders are recommended for lifting lengths of timber, pipe or steel. If a spreader is not available, double wrap the sling around the load before lifting.

Do not bash the eye of a sling down at the nip point. This practice will decrease the SWL and damage the sling.

Use packing or lagging to prevent the sling from coming into contact with sharp edges. This will lengthen the life of the sling.

When using synthetic lifting slings, packing should be used for all loads.

Make sure that packing or lagging is secure so that it will not fall out when the slings go slack. Before lifting a load make sure that it is not caught or trapped in some way.

Basket hitches should not be used where people may be located near a lifted load, unless the sling is positively restrained from sliding along the load.

Sheets of plasterboard may be lifted in a specifically designed material box.

If a material box is not used, then the lifting system must:

Loads of structural steel (universal beams, RSJ’s) on trucks must have restraining spikes fitted in the truck to prevent them from falling out. Removing the securing chains or straps if there are no restraining spikes in place is very dangerous.

Structural steel can be very dangerous. When a load arrives on site, walk around the truck and check that the steel has not shifted into a dangerous position. Many serious accidents occur as load binding chains are removed from steel beams.

Deep beams that are narrower in width than height are unstable and can inflict severe injuries.

Always lift bundles of steel level. Do not lift vertically or at an angle. It is not possible to make the inside lengths of steel in a bundle tight enough to prevent them falling out if the bundle is at an angle.

Steel can kill if it falls.

As a load of steel is lifted keep hands well away. Steel sections tend to snap together or roll up as the sling bites into the nip.

Loads of loose items such as scaffold clips must be raised in properly constructed boxes branded with the SWL.

Materials should not be stacked higher than the side of the material box unless they are adequately secured, but at no time should the material box become top heavy.

Do not lift loads of this kind in 200 litre drums because:

Rubbish bins should have proper lifting lugs and be branded with the SWL. Rubbish bins that are overloaded must not be lifted. Where rubbish can be blown out or spill from a bin, secure the load before lifting, especially in windy conditions.

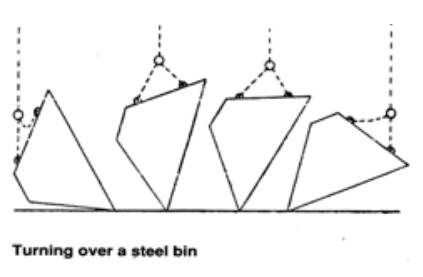

Sling rubbish bins with a four-legged sling. To tip the bin, release the two front slings and raise the bin with the two back slings.

Do not stand behind a bin when tipping rubbish out. It could whip back suddenly as it clears the ground.

Steel plate can be lifted with:

Note: plate clamps should never be used to lift loads over people.

Do not use home-made type plate clamps or plate dogs.

Remember that steel plate can injure or kill.

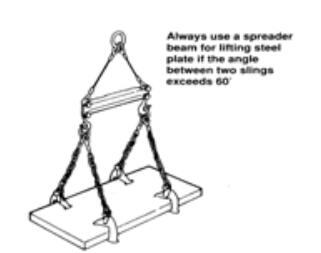

Use a spreader beam if the angle between the legs of a sling is likely to be more than 60°.

Steel plate can be lifted vertically or horizontally.

It is recommended that a minimum of four plate clamps and a spreader beam are used for lifting steel plate horizontally. For horizontal lifts, use appropriate plate clamps. Use a spreader beam for long thin plates to prevent dangerous flapping, sagging and vibration.

Lifting vertically

Use an appropriate plate clamp where a sling cannot be attached and there is no lifting hole. An example is the dished and flanged end-plate for a pressure vessel.

Note: It can be difficult to remove or attach a sling where plate is stored vertically in a rack or is to be fed into bending rolls.

As a plate touches the ground and the tension is released from the slings, a single hook can come out of the hole causing the plate to fall. To prevent this, lift with a hook through a ring that is attached to a short length of chain shackled to an approved plate clamp.

Always make sure that the tension remains in the slings until the plate is in place.

wide variety of loads are delivered on pallets. Before a paletted load is lifted check that the:

The SWL can be dramatically reduced if there are any missing boards or any other defects.

Note: some pallets are designed for packaging notlifting.

To lift a load on a damaged pallet, raise the load and pallet to reposition onto an undamaged pallet. Then lower the load and sling properly before lifting and moving the load to the desired place.

If no spare undamaged pallets are available, do not lift the load; send it back to the supplier to be repaletted.

Always raise paletted bricks inside a brick cage to prevent loose bricks falling.

When placing concrete from a kibble into formwork, spread the flow out. Dumping the whole load in one spot can overload the formwork, especially if it is also taking the weight of workers and vibrating equipment. Formwork is only designed to take concrete spread out evenly over the whole area.

Make sure that the concrete is poured gradually. The sudden release of concrete from a kibble attached to a mobile or tower crane can cause a ‘whip back’ causing the kibble to bounce dangerously.

When turning over a load such as a steel beam, the sling must be attached to the hook on the side of the load that is to be lifted. This will ensure that it is raised on a diagonal through the centre of gravity. It is then a simple matter to lower the lifting medium turning the load over in a safe and controlled manner.

Sling the load so that when the load is lowered, the nip will pull against the eye.

A long narrow load such as a steel beam ( has a high centre of gravity and a narrow when it is standing on its flange. If a dogger nips the sling incorrectly to turn the beam (or any other load) it will flop, topple over an possibly break the slings.

Turning over a steel bin

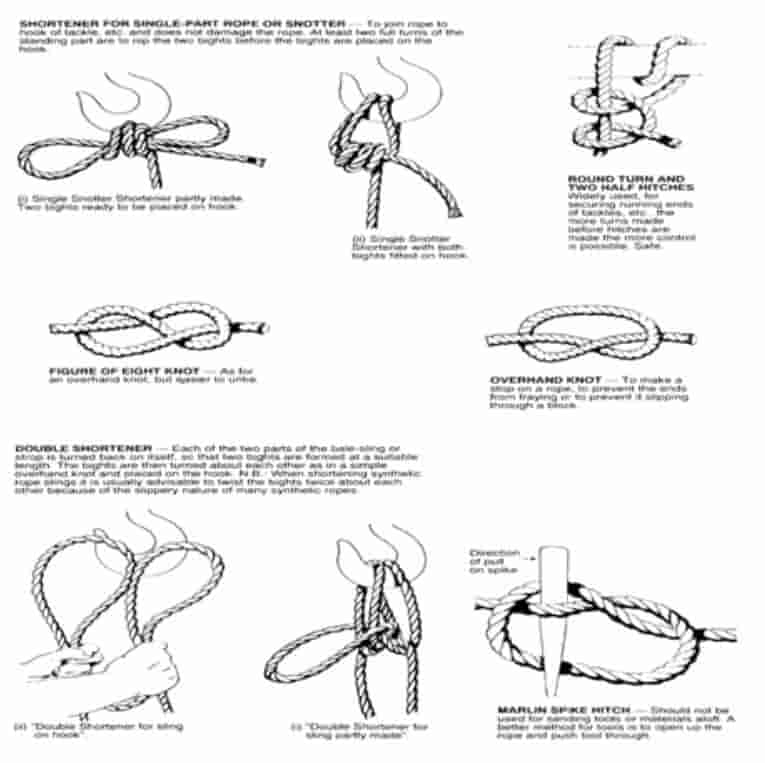

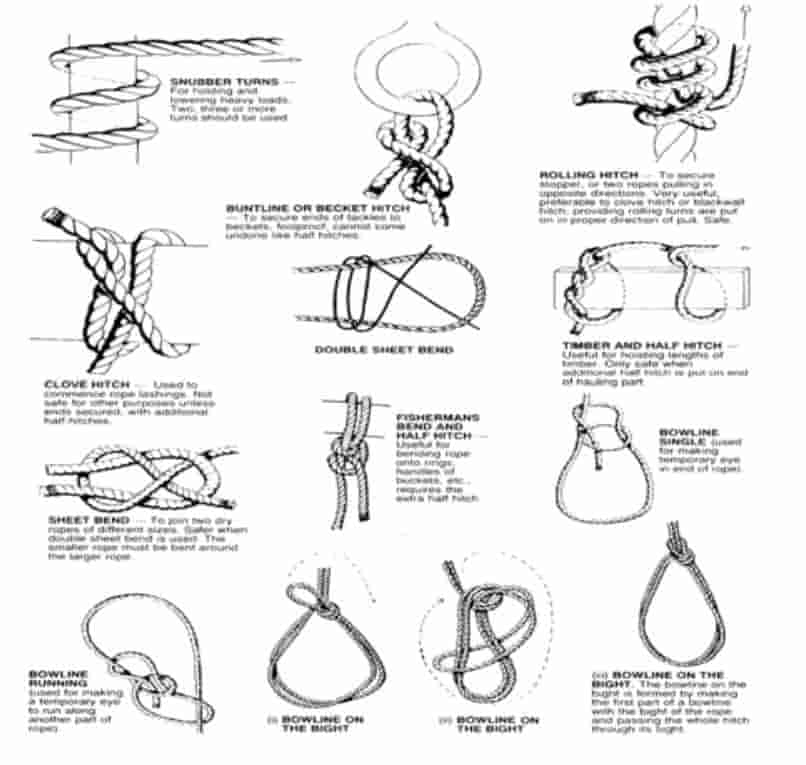

Learn those described and illustrated below.

Contact our crane specialists

Send us a message and we will get back to you as soon as possible.