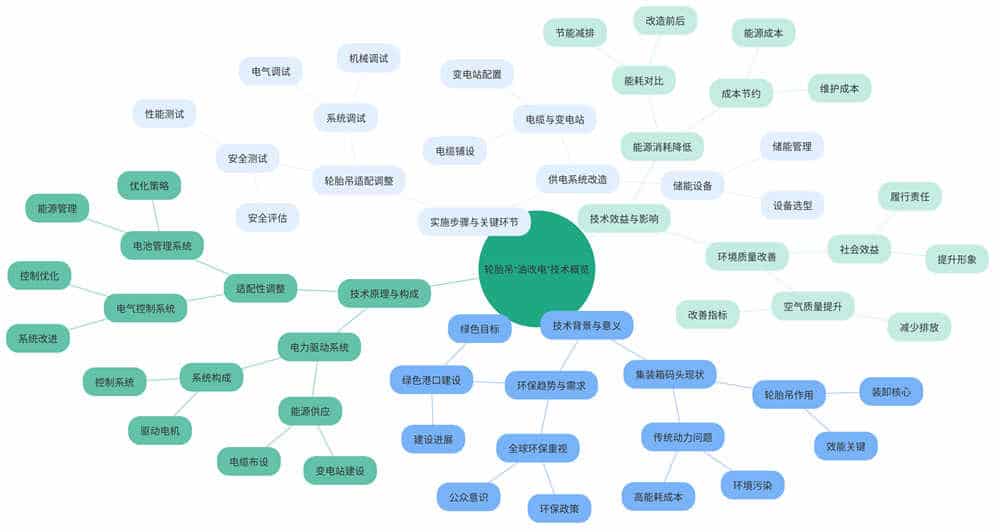

With the increasing awareness of environmental protection and the transformation of energy structure, the “oil to electricity” conversion of rubber tire gantry cranes in container terminals has become an inevitable trend in industry development. This change aims to reduce carbon emissions, improve energy efficiency, and lower operating costs. As a key equipment for dock operations, the transformation of the power system of rubber tire gantry cranes not only involves technological innovation, but also involves the overall layout and efficiency optimization of dock operations. Faced with various “oil to electricity” schemes, how to scientifically choose to achieve a win-win situation of economic and environmental benefits has become an urgent problem to be solved. This article will delve into the characteristics of different “oil to electricity” conversion schemes, analyze the influencing factors of scheme selection, and provide useful references for the “oil to electricity” conversion of rubber tire gantry cranes in container terminals through practical cases.

At container terminals, rubber tire gantry cranes are the core equipment for loading and unloading operations, and their operational efficiency and environmental performance play a decisive role in the overall efficiency and environmental protection of the terminal. Traditional rubber tire gantry cranes rely on diesel engines for power, which not only brings high energy consumption costs, but also generates a large amount of exhaust emissions, causing certain pollution to the environment.

With the increasing global attention to environmental issues and the active promotion of green port construction, the “oil to electricity” technology for rubber tire gantry cranes has emerged and gradually become an important direction for upgrading and renovating port loading and unloading equipment. This technology has significantly reduced energy consumption and effectively reduced harmful gas emissions by introducing an electric drive system to replace the original diesel power system. It has positive implications for optimizing the energy structure of ports, improving air quality, and fulfilling social responsibilities.

The implementation of the “oil to electricity” technology for rubber tire gantry cranes involves multiple key links: firstly, the transformation of the power supply system, including the installation of cables, construction of substations, and configuration of energy storage equipment, to ensure stable and reliable power supply; Secondly, the adaptability adjustment of the rubber tire gantry crane itself, such as improving the electrical control system, optimizing the battery management system, etc., to meet the needs of pure electric drive; Finally, through intelligent management methods, seamless integration between the rubber tire gantry crane and the power system can be achieved to ensure efficient loading and unloading operations.

In short, the “oil to electricity” technology for rubber tire gantry cranes is not only an equipment upgrade, but also a profound change in the port loading and unloading operation mode. It effectively promotes the construction of green ports and promotes the sustainable development of the logistics industry.

The cable reel power supply scheme is a solution that installs cable reels on rubber tire gantry cranes to automatically retract and release cables as the crane moves. This scheme has the advantages of simple structure and low initial investment, but is limited by cable length and weight, and the operating range of rubber tire gantry cranes is restricted, making it impossible to carry out long-distance operations. In addition, due to the frequent need to retract and unwind cables, it is easy to cause cable wear and tear, which increases maintenance costs.

The low rack sliding contact line scheme is a scheme of laying the power supply line on the ground or low support, and the rubber tire gantry crane obtains power by contacting the sliding contact line through a collector. This plan can effectively expand the operating range of rubber tire gantry cranes and reduce cable wear, but it may be affected by ground obstacles, and the contact stability between the current collector and the sliding contact wire needs to be given special attention. In practical applications, corresponding measures need to be taken to ensure contact stability, such as adding pressure regulating devices to the current collector.

The middle rack sliding contact line scheme is a scheme of installing the power supply line on a certain height bracket, which not only avoids the interference of ground obstacles but also maintains good operational flexibility. This plan has improved both safety and operational efficiency, but compared to the low rack plan, the initial investment and maintenance costs have increased. The disadvantage of the power supply scheme for the middle rack sliding contact line is that it has a limited scope of application and is only suitable for certain specific situations, such as indoor operations.

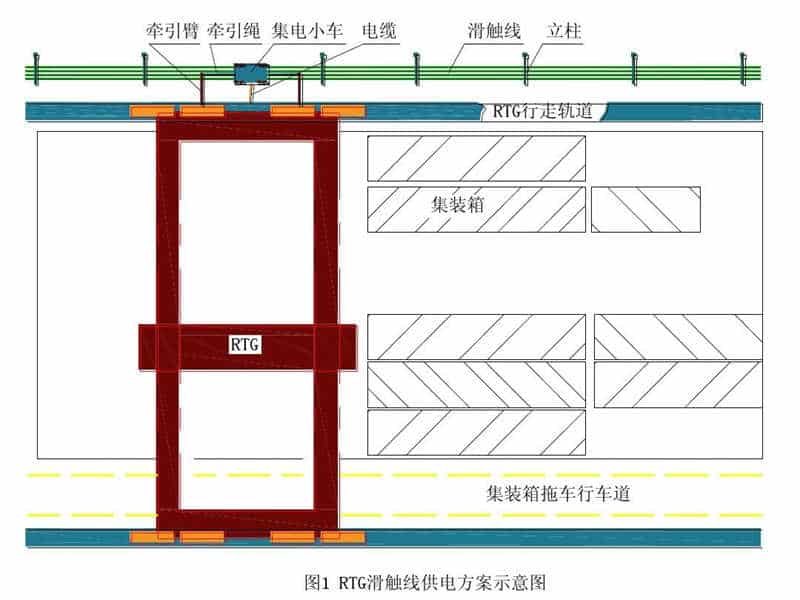

The elevated sliding contact line scheme is a method of installing power lines at high altitudes, which is almost not limited by the ground environment. The rubber tire gantry crane has the largest operating range and reduces the occupation of ground space. However, this solution requires high installation accuracy and maintenance, and has the highest investment cost, making it suitable for large and busy container terminals. The advantage of the elevated sliding contact line power supply scheme is that it can adapt to various complex working environments, improving work efficiency and safety.

Comparison Table of Different Power Supply Plans

| Power supply plan | Describe | Advantage | Disadvantage | Scope of application |

| Power supply scheme for cable reel | Install cable reels on rubber tire gantry cranes to automatically retract and unwind cables as the crane moves | Simple structure, low initial investment | The scope of work is limited, cables are prone to wear and tear, and maintenance costs are high | Small or medium-sized venues |

| Low rack sliding contact line power supply scheme | The power supply line is laid on the ground or low supports, and the rubber tire gantry crane obtains power through contact with the collector | Expanded scope of work, reduced cable wear | Possible impact from ground obstacles, contact stability needs to be considered | A flat and obstacle free site |

| Power supply scheme for middle frame sliding contact line | The power supply line is installed on a bracket at a certain height | Improved safety and operational efficiency | The initial investment and maintenance costs are relatively high, and the scope of application is limited | Indoor assignments or specific occasions |

| Power supply scheme for elevated sliding contact line | The power supply line is installed at high altitude | The maximum scope of work is not limited by the ground environment, which improves work efficiency and safety | High installation accuracy and maintenance requirements, with the highest investment cost | Large and busy container terminals |

Key points for implementing the power supply plan

| Power supply plan | Key points of installation | Maintenance points | Precautions |

| Power supply scheme for cable reel | Ensure the stability of the cable reel structure and smooth cable retraction and loading | Regularly inspect cable wear and replace worn cables in a timely manner | Pay attention to the limitations of cable length and weight on the scope of work |

| Low rack sliding contact line power supply scheme | Ensure smooth laying of the sliding contact line and good contact between the current collector and the sliding contact line | Regularly check the contact stability between the current collector and the sliding contact wire, and adjust the pressure regulating device | Pay attention to the impact of ground obstacles on homework |

| Power supply scheme for middle frame sliding contact line | Ensure that the bracket is stable and the installation height of the power supply line is appropriate | Regularly check the stability of the bracket and power supply line, and maintain the current collector | The scope of application is relatively small and needs to be selected according to specific situations |

| Power supply scheme for elevated sliding contact line | Ensure installation accuracy and stable installation of power supply lines | Regularly inspect the maintenance of elevated structures and power supply lines | The investment cost is high and needs to be selected based on the size and demand of the site |

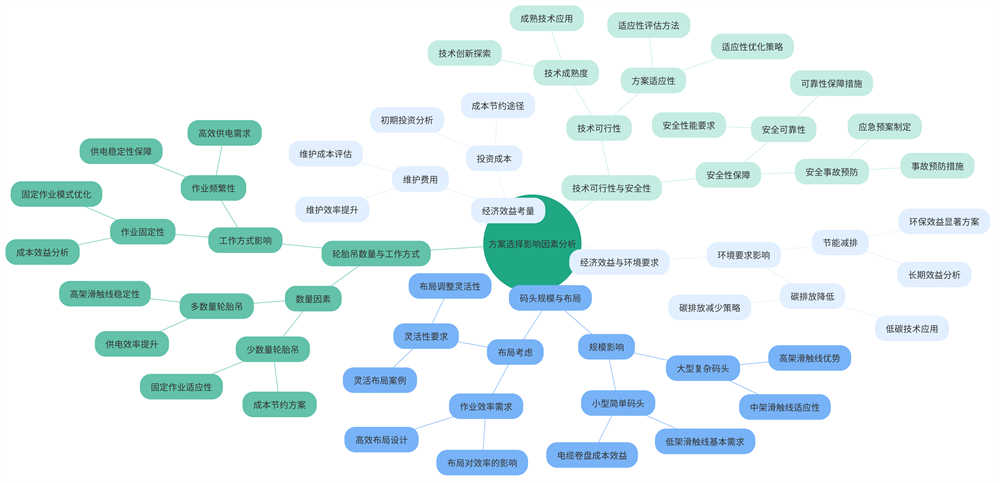

The scale and layout of the dock are one of the key factors affecting the selection of the “oil to electricity” plan. Large and complex docks require higher operational efficiency and flexibility, so it is more inclined to choose elevated or mid frame sliding contact line solutions. These solutions can provide stable power supply while adapting to various operational needs on the dock. In contrast, small and simply laid out docks may be more inclined to choose lower cost cable reels or low rack sliding contact line solutions. Although these schemes may not be as stable and flexible as elevated or mid frame sliding contact line schemes, they can meet basic operational needs and have lower costs.

The number and working mode of rubber tire gantry cranes are also important factors affecting the selection of the “oil to electricity” plan. If there are a large number of rubber tire gantry cranes on the dock and their operations are frequent, a more stable and efficient power supply solution is needed, such as elevated sliding contact lines. This can ensure that the rubber tire gantry crane will not experience power supply interruptions during operation. On the contrary, if there are fewer rubber tire gantry cranes on the dock and their operations are relatively fixed, a lower cost solution can be chosen.

In addition to technical factors, the economic benefits and environmental requirements of the “oil to electricity” plan cannot be ignored. While considering investment costs and maintenance expenses, it is also necessary to weigh the long-term benefits of energy conservation and emission reduction. Especially in areas with high environmental requirements, even if the initial investment is large, priority should be given to solutions with significant environmental benefits. This can reduce the carbon emissions of the dock and minimize environmental pollution.

Technical feasibility and safety are the basis for selecting the “oil to electricity” plan. The selected plan must ensure mature technology, safety and reliability, and avoid safety accidents or work interruptions caused by technical defects. In the process of selecting a solution, it is necessary to fully consider the feasibility and safety of the technology to ensure the effectiveness and reliability of the solution.

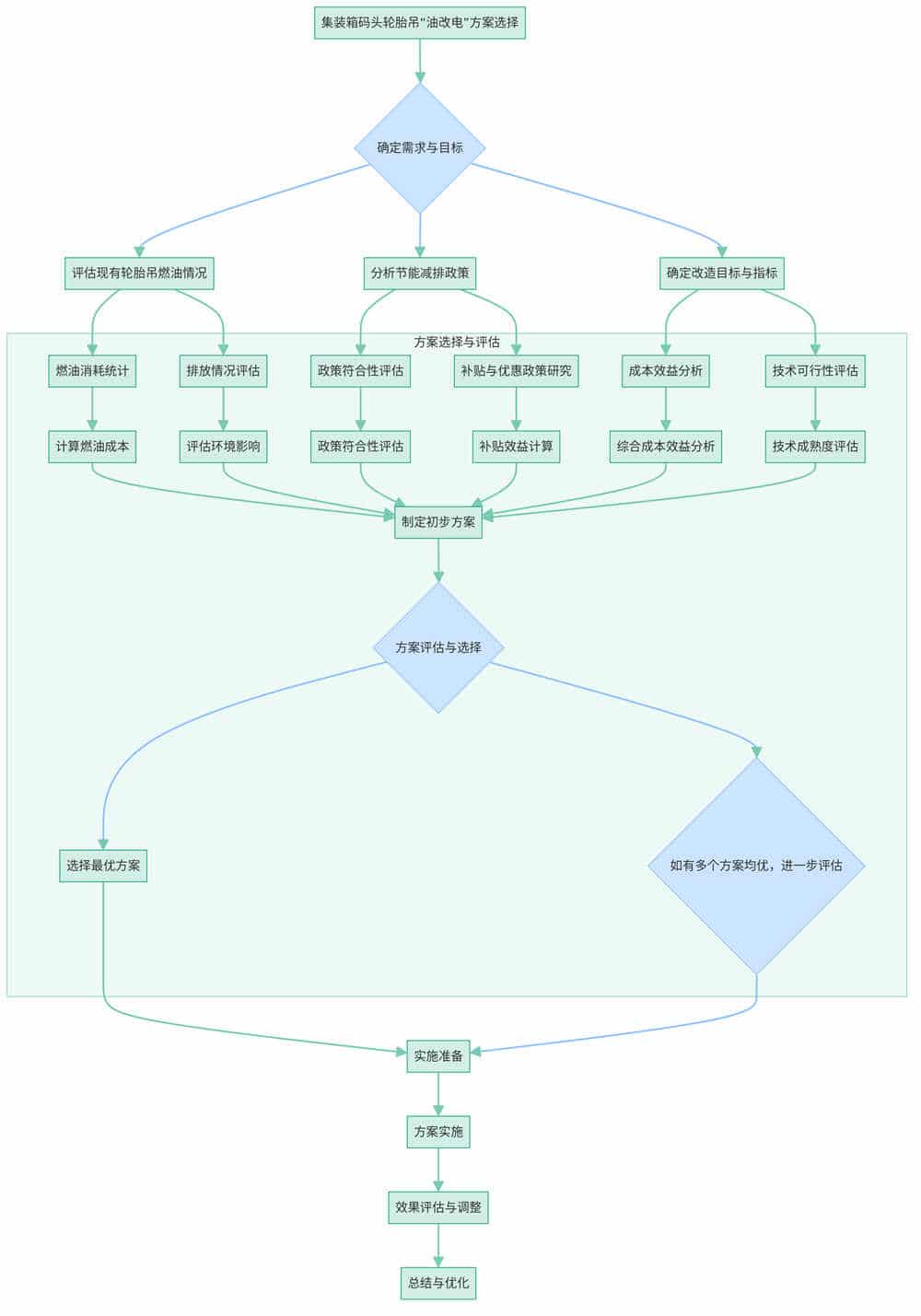

As a large domestic container terminal, Ningbo Zhoushan Port Chuanshan Port Area has taken the lead in implementing the “oil to electricity” project for rubber tire gantry cranes. This measure marks an important step forward for the port area in terms of environmental protection and energy conservation. The implementation of the “oil to electricity” project for rubber tire gantry cranes not only helps reduce air pollution and energy consumption, but also improves operational efficiency and enhances port competitiveness.

When choosing the “oil to electricity” project plan for rubber tire gantry cranes, Chuanshan Port fully considered its own scale and layout. In order to ensure operational efficiency and flexibility, the port area has chosen an elevated sliding contact line power supply scheme. This scheme provides power to rubber tire gantry cranes through elevated sliding contact lines, avoiding the trouble of cable dragging and improving operational efficiency. At the same time, in order to ensure power supply stability and safety, the port area has also optimized the design of the current collector.

In response to the transition requirements of rubber tire gantry cranes between different work areas, a mobile power supply device has been adopted in Chuanshan Port Area. This device can be moved to the working area of the rubber tire gantry crane at any time, achieving power supply for the rubber tire gantry crane during the transition process. This solution not only avoids the trouble of cable dragging, but also ensures the continuity of the operation. At the same time, the mobile power supply device also has the characteristics of strong flexibility and easy operation, providing reliable power guarantee for the transition operation of rubber tire gantry cranes.

After implementation, the “oil to electricity” project has significantly reduced energy consumption and emissions in the Chuanshan Port area. According to statistics, after the implementation of the project, the energy consumption in the port area decreased by about 30% and emissions decreased by about 20%. At the same time, the efficiency of homework has also been improved, and the operating time of rubber tire gantry cranes has been reduced by about 10%. These achievements fully demonstrate the feasibility and effectiveness of the “oil to electricity” project for rubber tire gantry cranes.

The successful implementation of this project has also provided valuable experience for other ports. When selecting a plan, full consideration should be given to the actual situation and future development needs of the terminal. At the same time, attention should be paid to technological innovation and talent cultivation to provide strong guarantees for the sustainable development of ports. In addition, cooperation and communication with relevant departments should be strengthened to jointly promote the green development of the port industry.

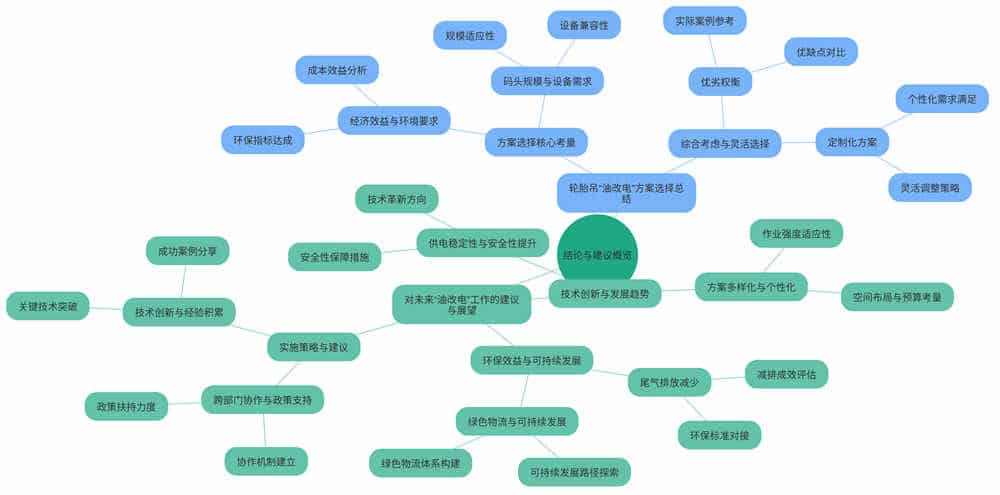

The core goal of the “oil to electricity” project for rubber tire gantry cranes is to reduce diesel consumption, lower emissions and pollution, while ensuring efficient and stable energy supply to meet the high-intensity demands of port operations. After in-depth analysis of various feasible solutions, it can be concluded that the selection of the “oil to electricity” plan for rubber tire gantry cranes is a comprehensive consideration process, which needs to be balanced based on multiple factors such as the size of the terminal, the number and working mode of rubber tire gantry cranes, economic benefits and environmental requirements, as well as technical feasibility and safety. Different plans have their own advantages and disadvantages, and flexible choices need to be made based on the actual situation.

The selection of the “oil to electricity” conversion plan for rubber tire gantry cranes is a complex and meticulous process that requires comprehensive consideration of multiple aspects such as dock scale, equipment requirements, economic benefits, environmental requirements, as well as technical feasibility and safety. Each port should consider its own actual situation, weigh various factors, and choose the most suitable solution to achieve the oil to electricity conversion of rubber tire gantry cranes, improve port operation efficiency, reduce environmental pollution, and promote the development of green logistics.

With the continuous advancement of technology and the deepening of the concept of green ports, the “oil to electricity” transformation of rubber tire gantry cranes will usher in new development opportunities and challenges. Looking ahead to the future, technological innovation will continue, and the stability and safety of power supply will be further improved; The selection of solutions will be more diversified to meet the personalized needs of different docks in terms of operational intensity, spatial layout, and investment budget; In terms of environmental benefits, through the large-scale implementation of the “oil to electricity” project, ports will significantly reduce exhaust emissions, improve surrounding environmental quality, and promote green logistics and sustainable development.

Therefore, it is recommended that ports pay attention to technological innovation and experience accumulation when promoting the “oil to electricity” project, and continuously improve the implementation effect and economic benefits of the “oil to electricity” project; At the same time, strengthen cross departmental collaboration and policy support to jointly promote the construction of green ports.

Contact our crane specialists

Send us a message and we will get back to you as soon as possible.