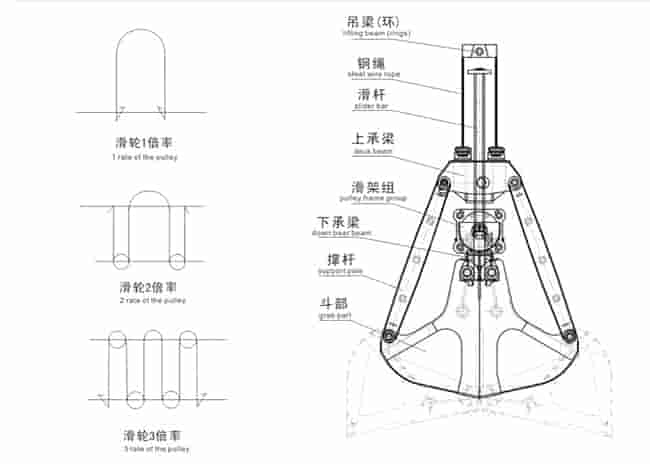

Single rope grab is a kind of grab commonly used in cranes, generally composed of hanging beam (ring), wire rope, sliding rod, upper bolster, sliding frame group, lower beam, brace, bucket, etc. Single-rope grabs mainly rely on the interaction of the sliding blocks, bumps, grooves and thimble of the grab to complete the unloading process. The editor introduces the working principle of the single beam grab.

Work flow of single rope grab:

1. Start by opening the grab bucket and putting it on top of the material. Due to gravity, the sliding block drops, and the bump is pushed by the thimble to form an angle of about 30°.

2. Lifting the steel wire rope, the entire sliding block moves up along the guide rail. After moving a small distance, the convex block and the groove are connected (the convex block rotates at a small angle again), driving the entire lower bolster to move up, completing the grab closing and grabbing .

3. When unloading, release the wire rope. At this time, the bottom of the grab first contacts the supporting surface. Due to gravity, the sliding block descends and the bump is pushed into a horizontal direction by the thimble (the grab is not opened)

4. When the steel wire rope is lifted, the sliding block moves upward, the cam is blocked by the groove to a vertical shape, and is located on both sides of the guide rail, so the sliding seat is separated from the lower bolster and moves upward toward the upper bolster. Due to the weight, the bucket flap opens and discharges.

5. The unloaded grab is open in the air, placed on top of the material, the sliding block descends, and the cam is pushed by the thimble at an angle of about 30° to complete a grabbing process

The working principle of the single rope grab is relatively simple. It is generally applied to single hook cranes, because the grab is not driven by electricity and cannot be opened and closed in the air.

Contact our crane specialists

Send us a message and we will get back to you as soon as possible.