What is a lifting electromagnet? Advantages and uses of lifting electromagnets

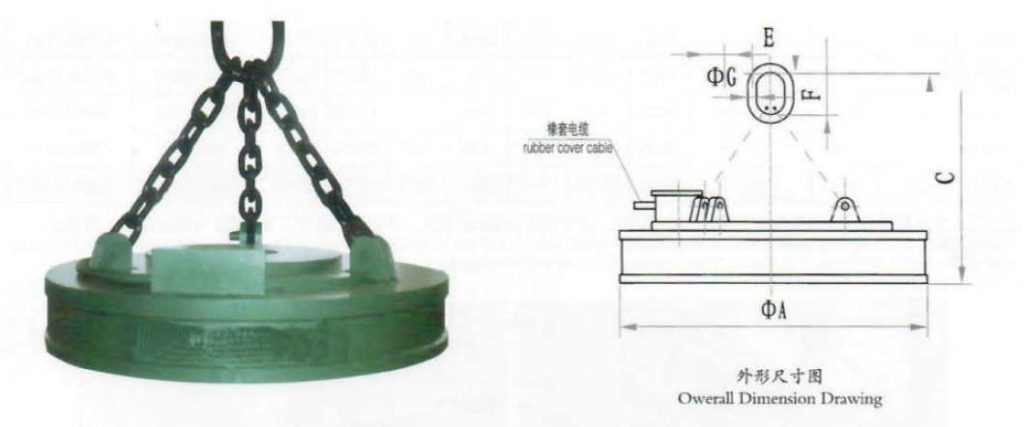

The lifting electromagnet is composed of a disc-shaped steel shell and an excitation coil in the shell. It is used to absorb magnetically conductive materials, also known as a lifting electromagnet. It is usually hung on a crane hook, and its cable rises and falls with the hook; Electromagnets are widely used in daily life.

The lifting electromagnet has an iron core inside and uses a coil with current to make it magnetic like a magnet is called an electromagnet. The iron core should be easily magnetized. Such electromagnets are magnetic when energized and disappear when they are de-energized.

According to the working principle, it can be divided into electromagnetic type and permanent magnet type. The electromagnetic type relies on the coil to pass the DC electric excitation to attract the material, and the power is turned off to demagnetize the material. In order to prevent the material from falling in the event of a power failure, cranes with such suction cups generally need to have a backup power supply. The circular electromagnetic chuck is used the most.

Advantages of lifting electromagnets

The presence or absence of magnetism of the lifting electromagnet can be controlled by on and off current; the magnitude of magnetism can be controlled by the strength of the current or the number of turns of the coil; the magnitude of the magnetism can also be controlled by changing the resistance to control the magnitude of the current; its magnetic pole can be controlled by Change the direction of the current to control, and so on. That is, the strength of magnetism can be changed, the presence or absence of magnetism can be controlled, and the direction of magnetic poles can be changed. When the iron core is inserted inside the energized solenoid, the iron core is magnetized by the magnetic field of the energized solenoid. The magnetized iron core also becomes a magnet, so that the magnetism of the solenoid is greatly enhanced due to the superposition of the two magnetic fields. In order to make the magnetism of the electromagnet stronger, the iron core is usually made into a hoof shape. However, it should be noted that the winding direction of the coil on the shoe-shaped iron core is opposite, one side must be clockwise, and the other side must be counterclockwise. If the winding directions are the same, the magnetization of the two coils on the iron core will cancel each other out, so that the iron core is not magnetic. In addition, the core of the electromagnet is made of soft iron, not steel. Otherwise, once the steel is magnetized, it will remain magnetic for a long time and cannot be demagnetized, so the strength of its magnetic properties cannot be controlled by the magnitude of the current, and the advantages of the lifting electromagnet will be lost.

The use of lifting electromagnets

- It is used for lifting and transporting magnetic conductive materials such as iron and steel in metallurgy, mining, machinery, transportation and other industries.

- It is used as an electromagnetic manipulator to hold magnetic conductive materials such as steel.

Characteristics of lifting electromagnets

- It adopts fully sealed structure and has good moisture-proof performance.

- The computer-optimized design has reasonable structure, light weight, large suction and low energy consumption.

- The excitation coil is treated by a special process, which improves the electrical and mechanical properties of the coil. The thermal grade of the insulating material reaches Class C, and the service life is long.

- The rated energization duration rate of ordinary electromagnets has been increased from 50% in the past to 60%, which improves the use efficiency of electromagnets.

- The ultra-high temperature electromagnet adopts a unique heat insulation method, in which the temperature of the object to be absorbed is increased by 700 °C from 600 °C in the past, which expands the application range of the electromagnet.

- Easy to install, operate and maintain.

Precautions for the use of lifting electromagnets

- The cold state insulation resistance of the electromagnet should be measured before use, and its value should not be less than 0.5MΩ at room temperature.

- Please do not energize before the magnet is placed on the surface to be attracted smoothly, and it is strictly forbidden to use the electromagnet as a freewheel.

- The electromagnet is not suitable for lifting the cutting head and scrap steel, because the electromagnet has a particularly strong suction force, and the electromagnet is heavy, and the cutting head or scrap steel can easily damage the radiant plate at the bottom of the electromagnet.

- The electromagnet should be placed at the center of gravity of the load as symmetrically as possible.

- The load capacity of the magnet = the suction capacity × (1 + eccentric distance/spacing), so the distance between the lifting electromagnets should be slightly larger. When the distance between the two electromagnets is small and the eccentricity is large, the load capacity of the two electromagnets is almost the same as that of one electromagnet, and it will be extremely unsafe to work. For occasions where the spacing cannot be expanded, the eccentricity should be minimized during operation to make the work safe and reliable.

- For long steels that are not easy to produce windings, the load of the electromagnet is relatively large, and multiple sets are generally used in combination. In this way, the level of the adsorption surface is very important, and a balance-type two-layer beam hanger should be used. Except for special reasons, four electromagnets are used in combination, which requires much less precision for hanging chains and the like, which is convenient for debugging and use in practice.

- When more than four electromagnets are used in combination for lifting, the electromagnetic adsorption surface should be carefully adjusted to adapt to the actual working conditions, otherwise individual electromagnets will not only fail to work, but will also increase their own weight and increase the burden on other electromagnets.

- When two sets are used together, the distance is half of the material length.

- It is required to use high temperature electromagnets to lift high temperature materials, use normal temperature electromagnets to lift normal temperature materials, and strictly use normal temperature electromagnets to lift high temperature materials.

- It is strictly forbidden to wait for the electromagnet to stay on the high temperature object. The high-temperature electromagnet can work close to the electromagnet when the temperature of the object to be absorbed drops below 600℃, and the ultra-high temperature electromagnet can only work close to the electromagnet when the temperature of the object to be absorbed drops below 700℃.

- When not in use, do not make the electromagnet stay, linger or store in the high temperature area.

- Try to shorten the contact time between the electromagnet and the high temperature object.

- Electromagnets with low energization rate cannot be used as products with high energization rate, and electromagnets with corresponding energization rate must be selected according to specific conditions.

- If the suction force of the ultra-high temperature electromagnet is significantly reduced or the magnetic pole is overheated during use, the electromagnet should be allowed to rest for a period of time, or the electromagnet pole should be immersed in a puddle with a depth of 300mm for cooling.

- As the electromagnet goes up and down with the crane, it is necessary to avoid breaking and breaking the cable.

- Regularly observe the voltage and current indication values on the electromagnet control screen during operation. The excitation current of the electromagnet should be between the cold state current and the hot state current. Voltage allowable error does not exceed ±10%.

- The electromagnet should be kept dry. After use, it should be placed in a dry, ventilated place without harmful substances.

- Always check the wear of chains and pins.